Smoke Exhaust Valve

The Smoke Exhaust Valve is a vital component for maintaining safety in buildings by effectively controlling smoke and gases during fire emergencies. This valve is essential for preserving air quality and enhancing visibility, providing crucial time for evacuation and firefighting efforts. It is important for facility managers and safety personnel to have a thorough understanding of its functionality, installation, and maintenance.

As a key safety feature in contemporary structures, the smoke exhaust valve plays a significant role in enhancing fire safety and indoor air quality. By becoming well-acquainted with its essential characteristics, proper operational procedures, and maintenance needs, facility managers can ensure that their smoke exhaust systems function optimally. Investing in high-quality smoke exhaust valves not only complies with safety regulations but also protects lives and property in emergency situations.

Make the safety of your building and its occupants a top priority by implementing effective smoke exhaust solutions today.

Smoke Exhaust Valve Parameter:

Contact Us For Detailed Dimensions

Key Characteristics of Smoke Exhaust Valve:

Effective Smoke Management

Smoke exhaust valves are highly effective at directing smoke and heat out of buildings, preventing the dangerous accumulation of these elements in occupied areas. By facilitating the swift exit of smoke, these valves improve visibility and air quality, allowing occupants to navigate safely during emergencies. Their strategic installation in stairwells and other vital locations ensures rapid smoke evacuation, providing crucial time for both evacuation and firefighting efforts.

Robust Design

Constructed from premium materials, smoke exhaust valves are engineered to endure extreme temperatures and harsh environmental conditions. This durability is essential during fire incidents, as the valves must withstand intense heat and potential exposure to corrosive substances. Their sturdy design ensures long-lasting reliability, reducing the frequency of replacements and repairs.

Automated Functionality

Many contemporary smoke exhaust valves feature advanced automatic activation systems that respond instantly to smoke detection. This capability ensures timely action during emergencies, activating the valve as soon as smoke is sensed, often before human intervention can occur. This automated response enhances safety and allows occupants to concentrate on evacuation without added stress.

Space-Saving Design

The streamlined and compact design of smoke exhaust valves allows for easy integration into diverse building architectures. Whether in high-rise buildings, commercial properties, or residential complexes, these valves blend seamlessly with existing structures without compromising visual appeal. Their unobtrusive nature ensures that safety measures enhance, rather than detract from, the overall aesthetic of the space.

Regulatory Compliance

Smoke exhaust valves are engineered to comply with strict fire safety codes and regulations, ensuring that buildings meet local safety standards. By incorporating these valves into fire protection systems, facility managers demonstrate their commitment to occupant safety and regulatory adherence. This proactive measure not only protects lives but also reduces the risk of legal liabilities associated with fire safety non-compliance.

Maintenance of Smoke Exhaust Valve:

Maintaining the smoke exhaust valve is crucial for ensuring its dependable operation. Here’s a detailed guide on effective maintenance practices:

Routine Inspections

- Schedule Regular Checks: Establish a routine inspection schedule to spot any obstructions or damage to the valve. This proactive approach helps identify potential issues before they become significant problems.

- Functionality Verification: During inspections, ensure the valve opens and closes smoothly without any hindrances. Proper movement is essential for effective smoke management during emergencies.

Cleaning

- Eliminate Contaminants: Regularly clean the valve and its surrounding area to remove dust, debris, or grease that could interfere with its operation. Keeping the area clear enhances the valve’s performance and longevity.

- Surface Maintenance: Pay attention to the surfaces of the valve, ensuring they are free of any buildup that might impede functionality. A clean valve is more likely to function correctly when needed.

Testing

- Periodic Function Tests: Conduct regular tests to confirm that the automatic activation system is working properly. This ensures that the valve will respond as intended during an emergency.

- Simulated Conditions: Occasionally simulate smoke conditions to assess the valve’s responsiveness. This testing helps verify that the system activates correctly and efficiently under realistic scenarios.

Professional Servicing

- Engage a Qualified Technician: Hire a certified technician to perform annual servicing of the smoke exhaust valve. Their expertise ensures that the valve is thoroughly checked and maintained.

- Comprehensive Evaluation: During servicing, the technician can conduct detailed inspections and make any necessary adjustments or repairs to keep the system in optimal condition.

By adhering to these maintenance practices, you can ensure that the smoke exhaust valve operates effectively, significantly enhancing safety within your building.

Smoke Exhaust Valve Application:

Smoke exhaust valves play vital roles across a variety of industries and building types, primarily by effectively managing smoke and heat to enhance safety and air quality. Here are some key applications:

1. Healthcare Facilities

In hospitals and clinics, maintaining optimal air quality is critical. Smoke exhaust valves are essential during emergencies, managing smoke to keep critical areas accessible and minimizing disruptions to patient care and safety.

2. Educational Institutions

Schools and universities utilize smoke exhaust valves to enhance safety in classrooms, laboratories, and auditoriums. These valves provide a dependable method for smoke management, ensuring the safety of students and staff during fire emergencies.

3. Industrial Facilities

In manufacturing plants and warehouses, where hazardous materials may produce toxic smoke, smoke exhaust valves are crucial. They efficiently vent smoke and heat, safeguarding both workers and equipment in these high-risk environments.

4. High-Rise Buildings

In tall structures, smoke exhaust valves are vital for controlling smoke that can rapidly rise and fill upper floors. Strategically placed in stairwells and atriums, these valves facilitate efficient smoke removal, improving visibility and air quality during emergencies.

5. Commercial Spaces

In office buildings, shopping malls, and hotels, smoke exhaust valves contribute significantly to occupant safety during fire incidents. They effectively channel smoke away from occupied areas, ensuring clear evacuation routes and assisting firefighters in their efforts.

6. Transportation Hubs

Airports, train stations, and bus terminals employ smoke exhaust valves to ensure passenger safety. These valves help maintain clear evacuation paths and enhance air quality in busy, high-traffic environments.

7. Residential Complexes

In multi-family dwellings, such as apartment buildings and condominiums, smoke exhaust valves improve fire safety by managing smoke in hallways and common areas. This ensures that residents can evacuate safely in the event of a fire.

These diverse applications highlight the importance of smoke exhaust valves in promoting safety and efficiency across various settings.

Fans Type:

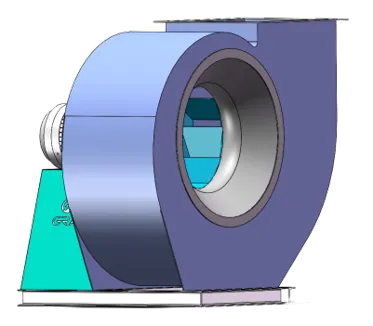

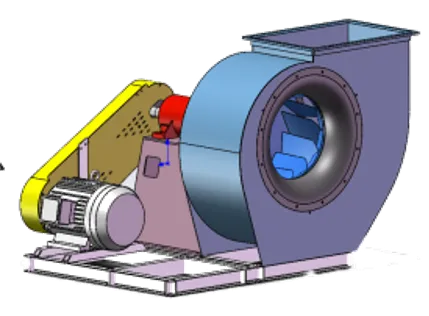

General centrifugal fans can be divided into low pressure (P≤1000Pa), medium pressure (P=1000-5000Pa), and high pressure (P=5000-30000Pa) according to the pressure. Low-pressure fans are generally 4-72, 4-73, 4-68, 4-79, and other backward blade series. Medium pressure fans are generally 5-51, 6-30, 6-41, 6-51, and other series; High pressure is generally 9-19, 9-26, 9-12, and 8-09 series. The low-pressure fan blades are mostly backward inclined blades, generally about 45 degrees. The outlet Angle of medium pressure fan is larger than that of low pressure fan. It is generally about 50 degrees, and the blades of the high-pressure fan are generally tilted forward less than 90 degrees. The advantages of medium and low-pressure fans are large flow, low noise value, not easy to overload, relatively stable operation, and use in general ventilation. High-pressure fans are used to supply forced air.

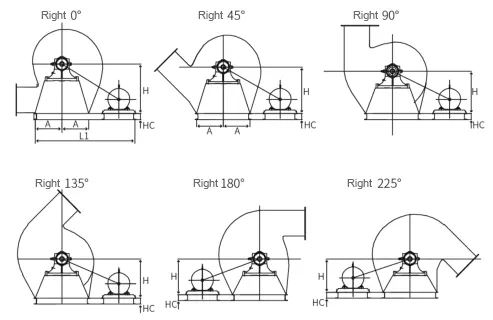

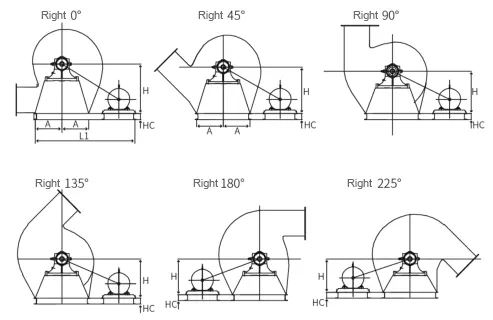

From the direction of the drive side (motor), the counterclockwise rotation is left, and the clockwise rotation is right.

The Angle is generally divided into 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

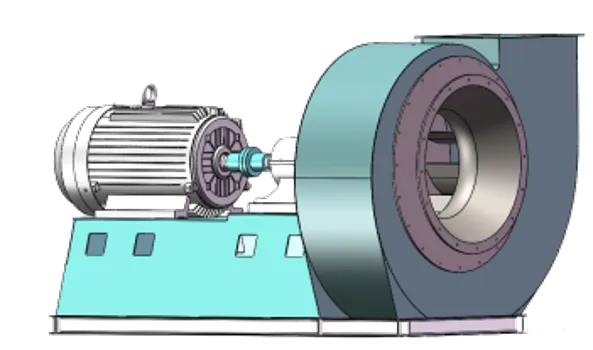

Type A Direct Transmission:

Type D Direct Transmission:

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

Low Pressure Fans:

Low-pressure fan series are 4-72 series, 4-73 series, and 4-79 series. Generally used for indoor ventilation in general factories and large buildings, it can be used as input gas, it can also be used as output gas, it can also be used as output gas, it can also be used for forced ventilation of boilers, forging furnaces, etc.

It is characterized by smooth operation, tight structure, low noise, flexible use, small footprint, high efficiency, and good performance in conveying air and other unnatural, harmless to the human body and non-corrosive gases.

Low-pressure fans are mostly used in garage air supply and exhaust systems, civil air defense ventilation systems, textile exhausts, grain warehouse dry exhausts, and other total air supply and exhaust systems.

Medium Pressure Fans:

The basic models of medium-pressure fans are 5-51 series, 6-51 series, 5-47/5-48 series, and 6-41 series. These models’ air volume and pressure are lower than those of the low-pressure series. Good aerodynamic performance, high efficiency, low noise, smooth operation.

G, Y6-51 type boiler feed fan is mainly used for 2~670t/h steam in thermal power plants.

The air supply system of the boiler also meets the requirements of the performance parameters of the high-pressure head of the fluidized bed furnace. change

Series fans can also be used for dust removal, mine ventilation, and general ventilation systems.

The blower transports air, and the induced draft fan transports gas containing impurity particles.

When the impurity concentration is less than 200mg/m³, it can be used for over 4 years. If the dust content is too large, the blade should be treated with wear-resistant treatment to extend its service life. G series fans are generally normal temperature; The maximum temperature of Y series induced draft fan shall not exceed 250℃. If more than 250℃. The impeller material should be changed.

High Pressure Fans:

Valve Factory:

Our unwavering commitment to excellence encompasses a comprehensive 24/7 on-site service, ensuring you immediate access to top-tier maintenance support whenever needed. We understand that operational efficiency is critical, so our team is always ready to assist you, regardless of the time or day.

Proactive Maintenance Approach

Detailed User Profiles: We take the time to develop thorough user profiles tailored to your specific systems and needs. This personalized approach allows us to understand the intricacies of your operations and tailor our support accordingly.

Regular Site Visits: Our team conducts routine site visits to monitor system performance and identify potential issues before they escalate. This proactive strategy ensures that we address any operational challenges swiftly, minimizing downtime and disruption to your workflow.

Comprehensive Support

Expert Technicians: Our highly trained technicians bring expertise and experience to every interaction, providing you with knowledgeable insights and effective solutions. You can trust that your systems are in capable hands.

Tailored Solutions: We prioritize your unique requirements, offering customized solutions that enhance your system’s performance and reliability. Our goal is to ensure that your operations run seamlessly.

With our dedicated support, you can enjoy peace of mind knowing that your success is our top priority. We are committed to fostering a collaborative partnership, where your needs drive our services. Our responsive support team is always just a call away, ready to assist with any challenges you may encounter.

Experience the difference that our comprehensive, proactive maintenance and exceptional support can make in your operations. Together, we will ensure your systems operate at their best, empowering your success every step of the way!