Smoke Vent

A Smoke Vent is an essential component for improving fire safety in buildings, specifically designed to facilitate the swift removal of smoke and heat during a fire. These advanced devices help reduce smoke damage, enhance visibility, and ensure safe evacuation for occupants. By understanding how they work, how to install them, and their maintenance needs, facility managers and safety personnel can significantly boost the safety standards of any facility.

Incorporating a smoke vent into your fire safety plan not only protects lives and property but also efficiently manages smoke and heat during emergencies. By familiarizing yourself with the key features and proper operation of smoke vents, you can ensure that your system functions optimally when it is most needed.

Investing in high-quality smoke vents not only aids in compliance with safety regulations but also offers invaluable peace of mind during critical situations. Prioritize fire safety in your building by implementing dependable smoke vent solutions today, safeguarding your environment against the devastating impacts of fire.

Smoke Vent Parameter:

Get in Touch for Specific Dimensions

Key Characteristics of Smoke Vent:

Effective Smoke Management

Smoke vents are vital in fire safety, efficiently directing smoke and heat outside a building. This proactive strategy prevents the buildup of hazardous smoke in occupied areas, significantly enhancing air quality and visibility during a fire. By enabling rapid smoke escape, these vents create safer environments for occupants and facilitate access for emergency responders.

Robust Durability

Constructed from high-quality materials, smoke vents are designed to endure extreme temperatures and challenging environmental conditions. Their sturdy build ensures long-lasting reliability, making them an integral part of any fire safety system. This durability not only protects the vent itself but also supports the overall structural integrity of the building during fire incidents.

Automatic Operation

Many contemporary smoke vents feature advanced automatic activation systems that promptly respond to smoke detectors. This capability ensures immediate operation, allowing for rapid smoke evacuation without the need for manual intervention. Such automatic responses are crucial in high-pressure situations, providing reassurance that the system will operate effectively when needed.

Flexible Design

Smoke vents come in a range of sizes and configurations, making them suitable for various building types and layouts. They can be customized to meet specific needs in residential, commercial, or industrial settings. This flexibility allows for seamless integration into existing fire safety systems, enhancing their overall effectiveness.

Adherence to Safety Standards

Smoke vents are engineered to comply with stringent fire safety regulations and standards, ensuring reliable performance during emergencies. Meeting these regulations not only enhances the safety of the building but also instills confidence in occupants and property owners. By investing in smoke vents that conform to industry standards, you contribute to a proactive fire safety strategy that prioritizes the well-being of everyone within the structure.

Maintenance of Smoke Vent:

Proper maintenance of smoke vents is essential to ensure their reliable operation during emergencies. Here are some key guidelines to follow:

1. Regular Inspections

- Monthly Checks: Conduct monthly inspections to identify any signs of damage, wear, or obstructions that could impede operation.

- Operational Testing: Ensure that the vent opens and closes smoothly, verifying that all moving parts function correctly.

2. Cleaning

- Routine Cleaning: Keep the smoke vent and its surrounding area clean by removing dirt, dust, and debris. This prevents blockages that could hinder performance.

- Clear Pathways: Ensure that any escape routes or areas around the smoke vent are free from obstructions.

3. Functional Testing

- Annual Testing: Perform comprehensive tests at least once a year to check the automatic activation features and ensure they respond correctly to smoke detectors.

- Simulated Emergency Drills: Conduct simulated emergency drills to train personnel on the operation of smoke vents and assess their effectiveness in practice.

4. Professional Servicing

- Scheduled Maintenance: Arrange for annual servicing by a qualified technician who can perform detailed inspections, necessary adjustments, and replacements of any worn components.

- Documentation: Keep records of all inspections, maintenance activities, and repairs to ensure compliance with safety regulations.

5. Compliance Checks

- Regulatory Review: Ensure that smoke vents comply with local fire safety regulations and standards. Regularly review and update systems as needed to meet any changes in regulations.

By adhering to these maintenance practices, you can enhance the reliability and effectiveness of smoke vents, ensuring they perform optimally when it matters most during a fire emergency.

Smoke Vent Application:

Smoke vents are crucial components in fire safety systems, designed to facilitate the safe escape of smoke and heat from buildings during a fire. Here are some key applications:

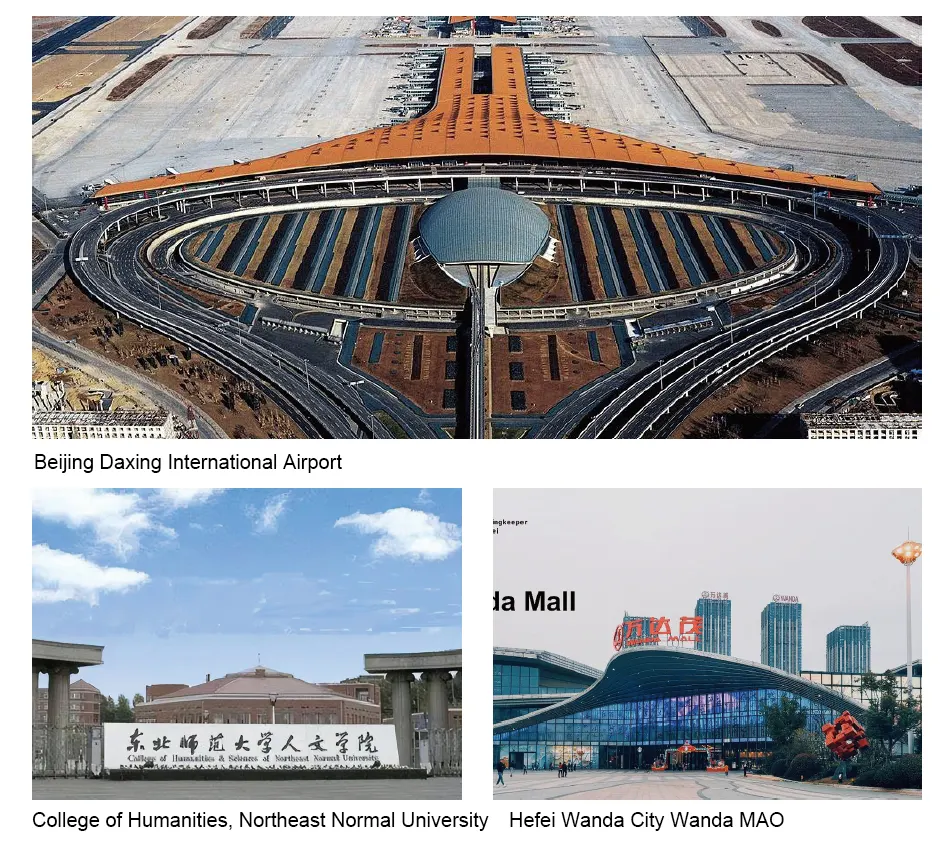

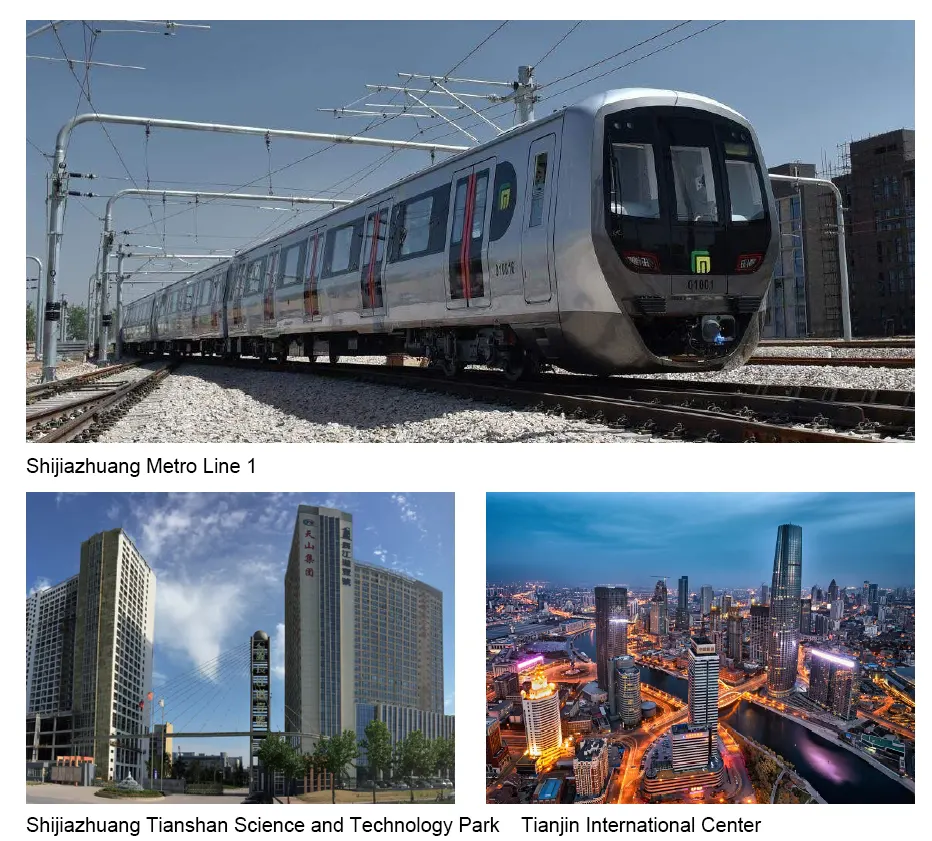

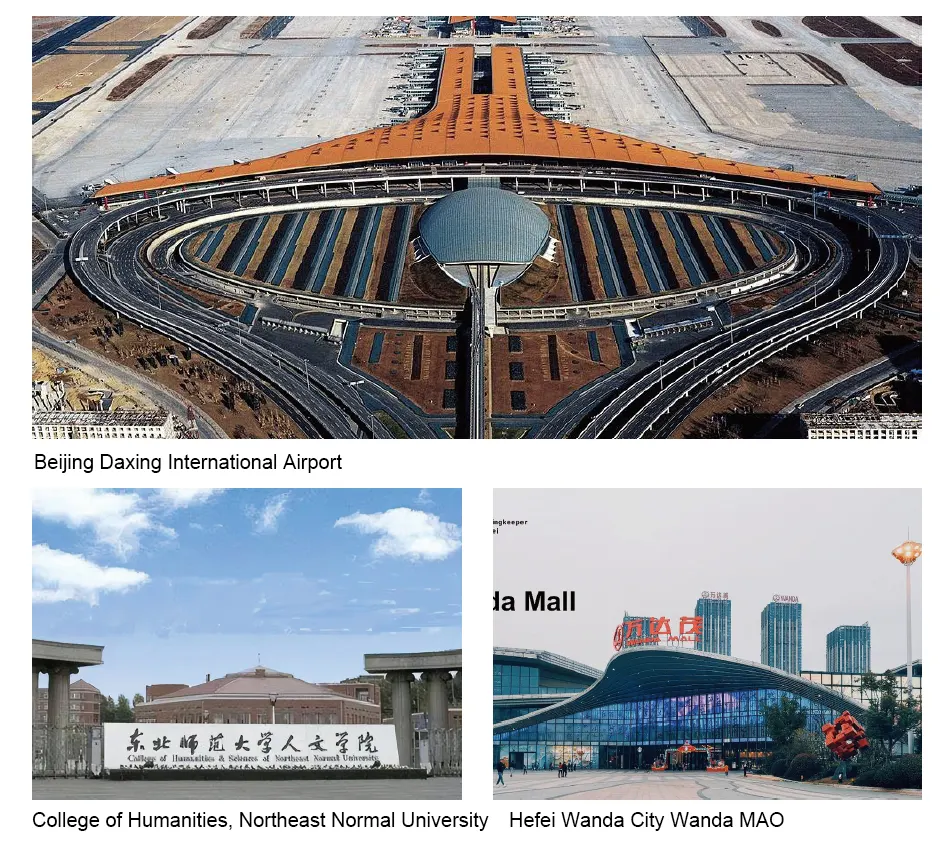

1. Commercial Buildings

In office complexes, shopping malls, and hotels, smoke vents help manage smoke release, ensuring that evacuation routes remain clear and safe for occupants during emergencies.

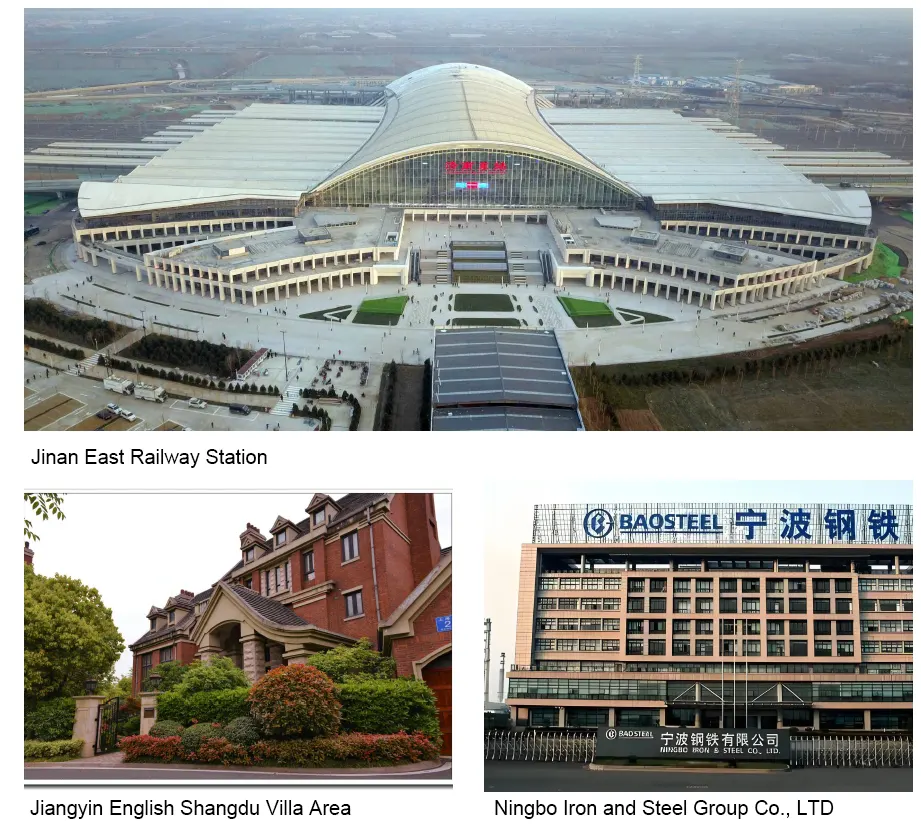

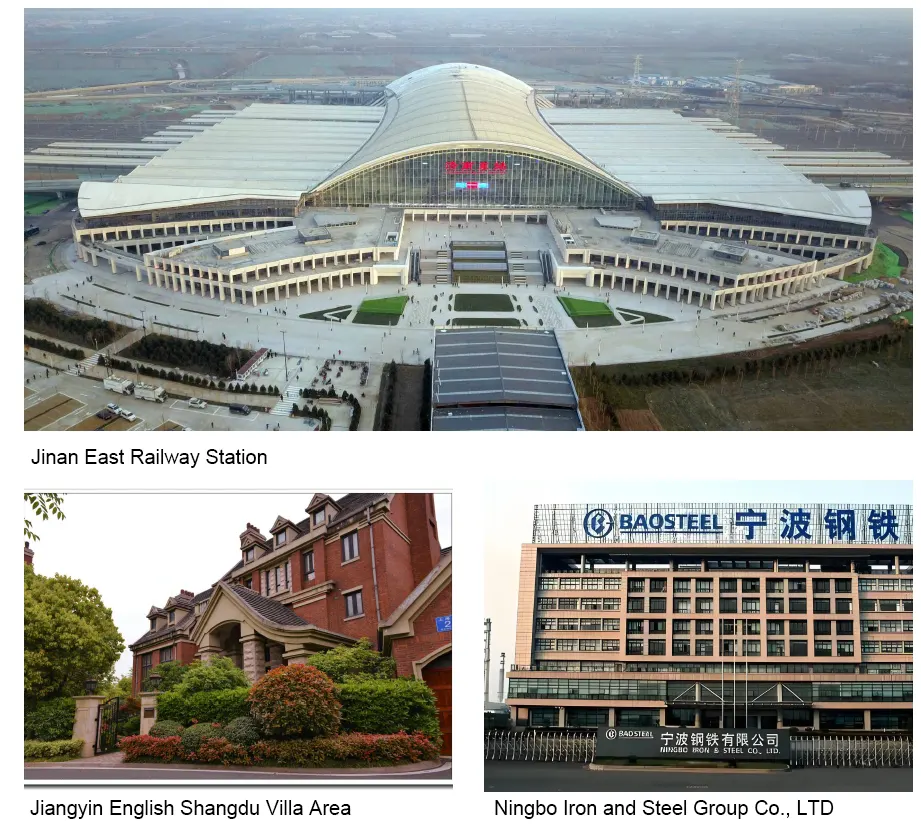

2. Industrial Facilities

Manufacturing plants and warehouses utilize smoke vents to protect large spaces filled with machinery and materials. By allowing smoke to escape rapidly, they safeguard both personnel and valuable assets.

3. Residential Properties

In multi-family residential buildings, such as apartments and condominiums, smoke vents are essential for maintaining safe conditions during a fire, aiding in the protection of residents and minimizing damage.

4. Healthcare Facilities

Hospitals and clinics depend on smoke vents to manage smoke and heat, ensuring that patient care areas remain protected and accessible for emergency responders.

5. Educational Institutions

Schools, colleges, and universities implement smoke vents in classrooms, laboratories, and auditoriums to enhance fire safety, helping to protect students and staff in case of a fire.

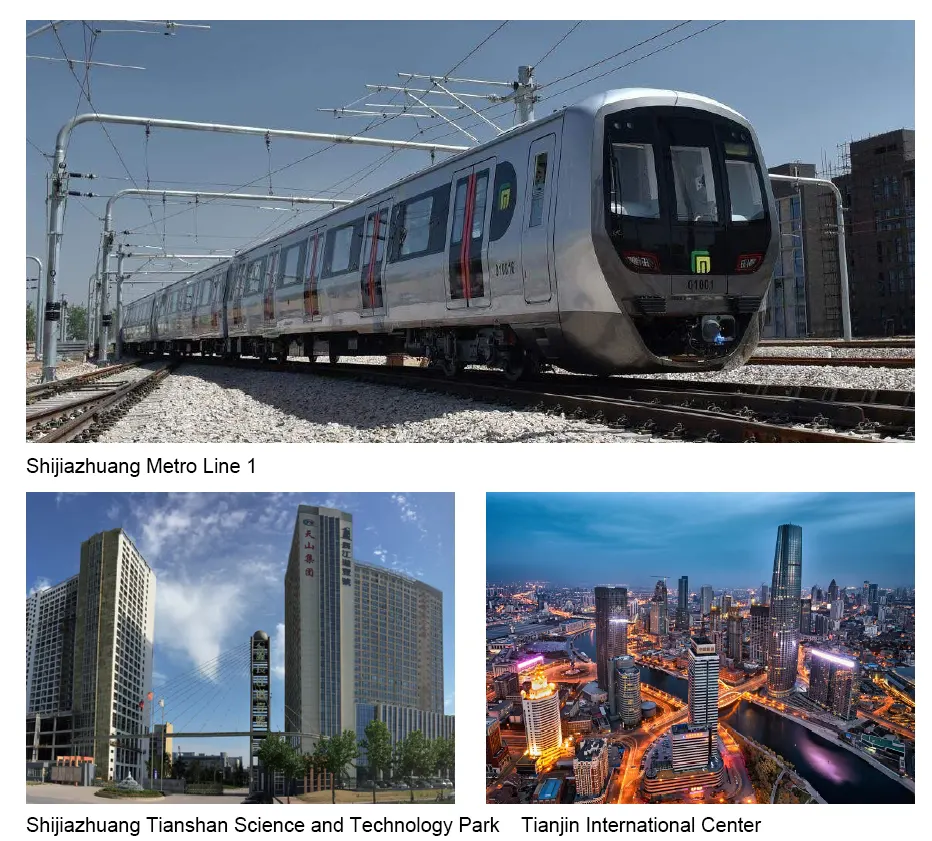

6. Transportation Hubs

Airports, train stations, and bus terminals incorporate smoke vents to ensure passenger safety and facilitate emergency evacuations, maintaining clear paths during fire incidents.

7. Data Centers

In data centers, smoke vents are critical for protecting sensitive electronic equipment from smoke damage, ensuring that fire suppression systems can operate effectively without harming vital infrastructure.

By integrating smoke vents into these various applications, organizations can significantly enhance their fire safety measures, ensuring compliance with regulations and safeguarding lives and property.

Fans Type:

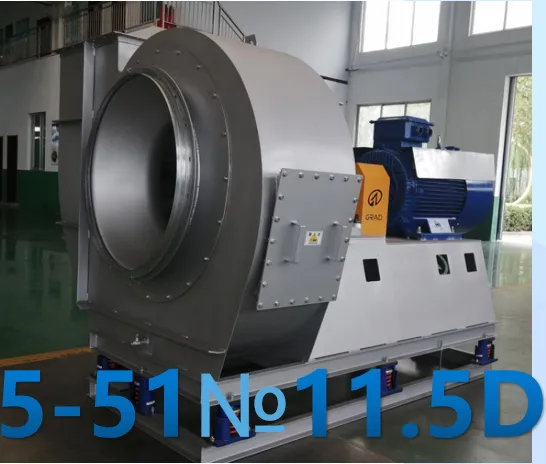

General centrifugal fans can be divided into low pressure (P≤1000Pa), medium pressure (P=1000-5000Pa), and high pressure (P=5000-30000Pa) according to the pressure. Low-pressure fans are generally 4-72, 4-73, 4-68, 4-79, and other backward blade series. Medium pressure fans are generally 5-51, 6-30, 6-41, 6-51, and other series; High pressure is generally 9-19, 9-26, 9-12, and 8-09 series. The low-pressure fan blades are mostly backward inclined blades, generally about 45 degrees. The outlet Angle of medium pressure fan is larger than that of low pressure fan. It is generally about 50 degrees, and the blades of the high-pressure fan are generally tilted forward less than 90 degrees. The advantages of medium and low-pressure fans are large flow, low noise value, not easy to overload, relatively stable operation, and use in general ventilation. High-pressure fans are used to supply forced air.

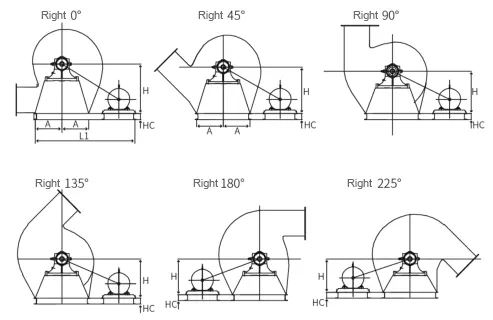

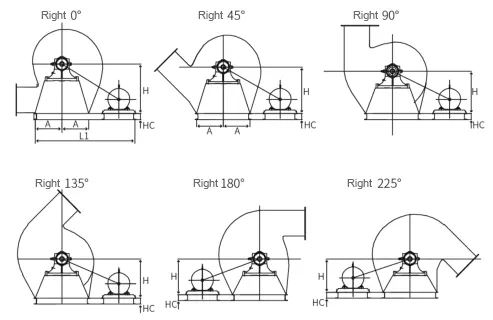

From the direction of the drive side (motor), the counterclockwise rotation is left, and the clockwise rotation is right.

The Angle is generally divided into 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

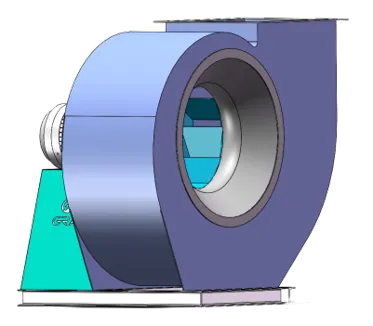

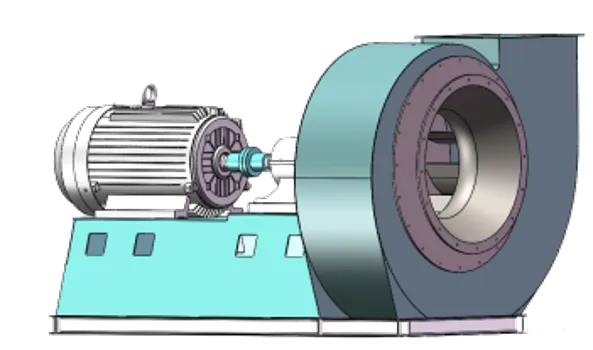

Type A Direct Transmission:

Type D Direct Transmission:

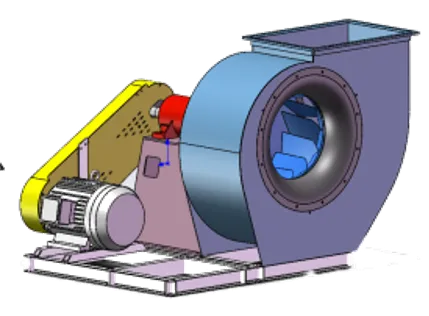

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

Low Pressure Fans:

Low-pressure fan series are 4-72 series, 4-73 series, and 4-79 series. Generally used for indoor ventilation in general factories and large buildings, it can be used as input gas, it can also be used as output gas, it can also be used as output gas, it can also be used for forced ventilation of boilers, forging furnaces, etc.

It is characterized by smooth operation, tight structure, low noise, flexible use, small footprint, high efficiency, and good performance in conveying air and other unnatural, harmless to the human body and non-corrosive gases.

Low-pressure fans are mostly used in garage air supply and exhaust systems, civil air defense ventilation systems, textile exhausts, grain warehouse dry exhausts, and other total air supply and exhaust systems.

Medium Pressure Fans:

The basic models of medium-pressure fans are 5-51 series, 6-51 series, 5-47/5-48 series, and 6-41 series. These models’ air volume and pressure are lower than those of the low-pressure series. Good aerodynamic performance, high efficiency, low noise, smooth operation.

G, Y6-51 type boiler feed fan is mainly used for 2~670t/h steam in thermal power plants.

The air supply system of the boiler also meets the requirements of the performance parameters of the high-pressure head of the fluidized bed furnace. change

Series fans can also be used for dust removal, mine ventilation, and general ventilation systems.

The blower transports air, and the induced draft fan transports gas containing impurity particles.

When the impurity concentration is less than 200mg/m³, it can be used for over 4 years. If the dust content is too large, the blade should be treated with wear-resistant treatment to extend its service life. G series fans are generally normal temperature; The maximum temperature of Y series induced draft fan shall not exceed 250℃. If more than 250℃. The impeller material should be changed.

High Pressure Fans:

Some Engineering Performance Of The Company:

About Us:

We proudly offer a comprehensive suite of professional services designed to meet the diverse needs of our clients and elevate operational performance. Here’s a closer look at what we provide:

Our Technical Consulting services deliver personalized advice tailored to your specific requirements. Our team of experts assesses your unique challenges and develops strategic solutions that align with your goals, ensuring you receive the guidance necessary for success.

We specialize in Innovative Solutions that introduce strategic approaches to enhance system performance. By leveraging cutting-edge technology and industry best practices, we help you optimize your operations, reduce downtime, and significantly improve overall efficiency.

Our System Operation Support offers expert guidance to ensure seamless operation. Our knowledgeable professionals can assist with troubleshooting, training, and operational best practices, enabling your team to maximize productivity and maintain high-performance levels.

Our Economic Analysis services provide in-depth assessments aimed at maximizing cost-effectiveness. We analyze your systems to identify areas for potential savings and improved return on investment, ensuring that your resources are utilized efficiently.

Our Design Optimization services enhance existing designs for improved efficiency and performance. Our team works closely with you to refine processes, increase reliability, and implement innovative solutions that drive results.

Our commitment to excellence shines through our 24-hour on-site service. We understand that operational challenges can arise anytime, so we provide top-notch maintenance support whenever you need it. Our dedicated team is just a call away, ready to resolve issues promptly and effectively.

We take a proactive approach by establishing detailed user profiles and conducting regular site visits. This allows us to identify potential operational challenges before they become significant, ensuring your systems run smoothly and efficiently.

With our dedicated support, you can experience true peace of mind. We prioritize your success and work tirelessly to ensure that your operations are functional and thriving. Partner with us to unlock the full potential of your systems and drive your business forward. Your success is our mission!