Circular Diffuser

The Circular Diffuser is essential in modern HVAC systems, designed to ensure efficient and uniform air distribution across various spaces. This innovative device greatly enhances indoor air quality and comfort by allowing precise control over airflow. Its sleek design and adaptability make it suitable for a wide range of settings, from residential homes to commercial buildings.

As a crucial component for effective air distribution, the Circular Diffuser offers numerous benefits. It provides consistent airflow, features adjustable settings, and boasts robust construction, making it an excellent choice for improving both comfort and air quality. By incorporating a circular diffuser into your HVAC system, you can create a more enjoyable indoor atmosphere while optimizing energy efficiency. Experience the benefits of enhanced airflow and transform your space today!

Circular Diffuser Parameter:

Get in Touch for Specific Dimensions

Key Characteristics of Circular Diffuser:

1. Choose the Optimal Location

To maximize airflow efficiency, select the most suitable location for the diffuser. Focus on areas prone to temperature variations or where airflow is inadequate. Ideal placements include:

- Central Positions: Installing the diffuser at the room’s center ensures even air distribution.

- Proximity to Heat Sources: Position the diffuser near heat-generating appliances to balance excess warmth.

- Common Areas: Ensure sufficient airflow in high-traffic spaces, such as living rooms or conference rooms, for enhanced comfort.

2. Inspect and Prepare the Ductwork

Before proceeding with the installation, conduct a thorough inspection and preparation of the ductwork:

- Clean the Ducts: Remove dust, debris, and blockages to optimize airflow.

- Check for Leaks: Identify and seal any leaks that could impact performance using duct tape or mastic.

- Accurate Measurements: Utilize a measuring tape to mark the precise dimensions for the diffuser installation, ensuring it aligns perfectly with the ductwork.

3. Create the Opening

With the location selected and the ductwork prepared, it’s time to cut the opening:

- Use Appropriate Tools: A drywall saw or utility knife will help you create a precise cut.

- Follow Safety Guidelines: Wear safety goggles and a mask to protect against dust and debris.

- Make the Cut: Carefully cut an opening in the ceiling or wall that matches the size of the circular diffuser, ensuring clean edges for seamless installation.

4. Secure the Diffuser

With the opening ready, it’s time to attach the diffuser:

- Align Properly: Position the circular diffuser over the opening, ensuring it aligns with the ductwork.

- Follow Manufacturer Instructions: Adhere to the specific guidelines provided by the manufacturer for installation.

- Ensure a Tight Fit: Use screws or clips to secure the diffuser firmly, checking that all connections are tight to prevent air leaks which can diminish efficiency.

5. Fine-Tune the Airflow

After installation, adjusting the airflow is crucial for optimal comfort:

- Adjust the Vanes: Modify the adjustable vanes on the diffuser to direct airflow toward preferred areas, enhancing comfort in line with room usage.

- Test Airflow Performance: Activate the HVAC system and assess the airflow. Make necessary adjustments to the vanes to achieve balanced distribution.

- Monitor and Adjust: Over the next few days, observe the room’s temperature and airflow. Make additional tweaks as needed to ensure consistent comfort.

Proper installation of a Circular Diffuser requires careful planning and execution. By selecting an ideal location, inspecting and prepping the ductwork, creating precise openings, securely attaching the diffuser, and fine-tuning airflow, you can significantly improve air distribution and comfort in any environment. This meticulous approach guarantees that the diffuser operates at its best, fostering a pleasant indoor atmosphere for everyone.

Usage Method of Circular Diffuser:

1. Choose the Location:

Identify the best position for the diffuser to ensure optimal airflow. Focus on areas that require improved air distribution to enhance overall comfort.

2. Prepare the Ductwork:

Thoroughly inspect the ductwork to ensure it is clean and free from any obstructions. Carefully measure and mark the area where the diffuser will be installed for precise fitting.

3. Create the Opening:

Utilize the right tools to cut an opening in the ceiling or wall that corresponds to the dimensions of the circular diffuser.

4. Attach the Diffuser:

Follow the manufacturer’s instructions to secure the circular diffuser to the ductwork. Make sure all connections are tight to prevent any potential air leaks.

5. Adjust the Airflow:

After installation, modify the vanes to direct the airflow as needed, ensuring optimal comfort throughout the space.

Operational Use

The Circular Diffuser effectively channels air from the HVAC system, distributing it uniformly across the room. Users can easily adjust both the direction and volume of airflow, allowing for customization based on specific preferences. This adaptability is particularly beneficial in larger areas, where maintaining consistent temperature control is crucial for overall comfort.

Circular Diffuser Application:

The Circular Diffuser is a versatile component designed to optimize air distribution and enhance indoor comfort across various environments. Here’s an exploration of its effective applications:

1. Residential Settings

- Kitchens:

Helps to dissipate heat and cooking odors, creating a pleasant atmosphere while cooking. - Living Rooms:

Ensures consistent airflow, reducing temperature fluctuations and providing comfort during family gatherings. - Bedrooms:

Offers customized airflow, allowing for tailored temperature settings that promote restful sleep.

2. Commercial Environments

- Retail Stores:

Regulates temperature and air quality to enhance customer experiences, making shopping more enjoyable. - Conference Rooms:

Provides focused airflow to maintain a comfortable environment, which is essential for productive meetings. - Offices:

Distributes air evenly in open-plan spaces, improving employee comfort and boosting productivity.

3. Industrial Applications

- Warehouses:

Ensures consistent ventilation, preventing heat accumulation and creating a more pleasant work environment. - Manufacturing Facilities:

Maintains effective air circulation in production areas, contributing to a safer and more comfortable workspace.

4. Healthcare Settings

- Clinics:

Enhances air quality in waiting and treatment areas, improving patient comfort and satisfaction. - Hospitals:

Provides clean, filtered air to patient rooms and surgical areas, essential for maintaining a sterile environment.

5. Educational Institutions

- Classrooms:

Ensures optimal ventilation and temperature control, fostering an effective learning atmosphere for students. - Auditoriums:

Maintains comfortable airflow during lectures and events, enhancing the experience for both speakers and attendees.

6. Data Centers

- Cooling Solutions:

Plays a crucial role in managing temperatures for servers and equipment, preventing overheating and ensuring reliable performance.

7. Agricultural Applications

- Greenhouses:

Regulates both humidity and temperature, promoting healthy plant growth and maximizing agricultural yields.

Circular diffusers are essential for enhancing air distribution and comfort across diverse settings. Their adaptability makes them a key component in residential, commercial, industrial, healthcare, educational, data, and agricultural environments.

Fans Type:

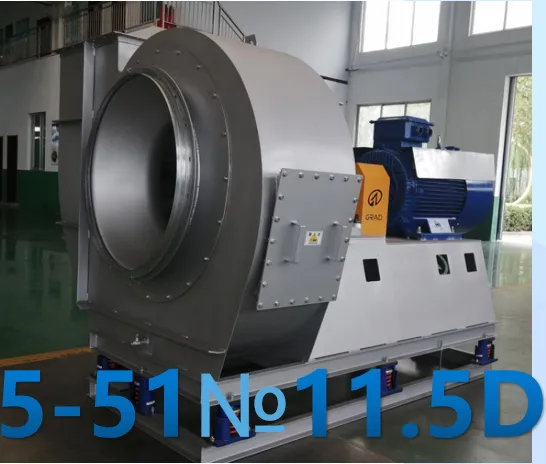

General centrifugal fans can be divided into low pressure (P≤1000Pa), medium pressure (P=1000-5000Pa), and high pressure (P=5000-30000Pa) according to the pressure. Low-pressure fans are generally 4-72, 4-73, 4-68, 4-79, and other backward blade series. Medium pressure fans are generally 5-51, 6-30, 6-41, 6-51, and other series; High pressure is generally 9-19, 9-26, 9-12, and 8-09 series. The low-pressure fan blades are mostly backward inclined blades, generally about 45 degrees. The outlet Angle of medium pressure fan is larger than that of low pressure fan. It is generally about 50 degrees, and the blades of the high-pressure fan are generally tilted forward less than 90 degrees. The advantages of medium and low-pressure fans are large flow, low noise value, not easy to overload, relatively stable operation, and use in general ventilation. High-pressure fans are used to supply forced air.

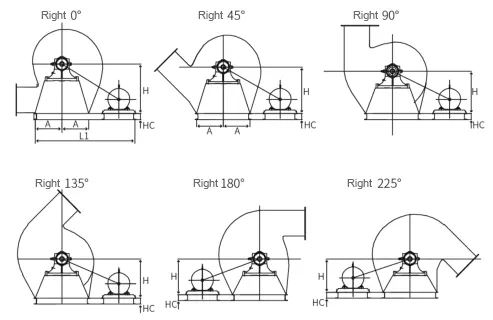

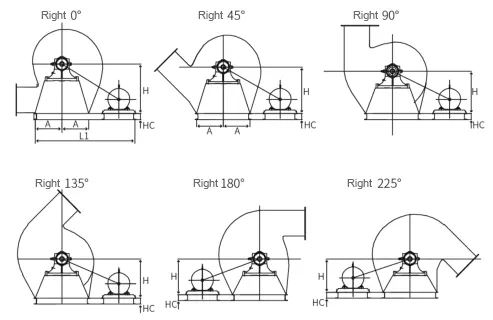

From the direction of the drive side (motor), the counterclockwise rotation is left, and the clockwise rotation is right.

The Angle is generally divided into 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

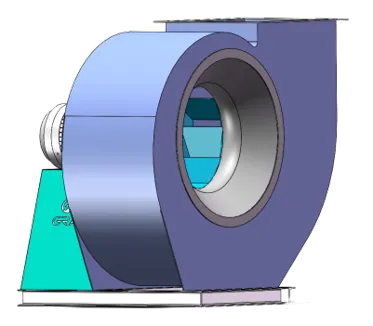

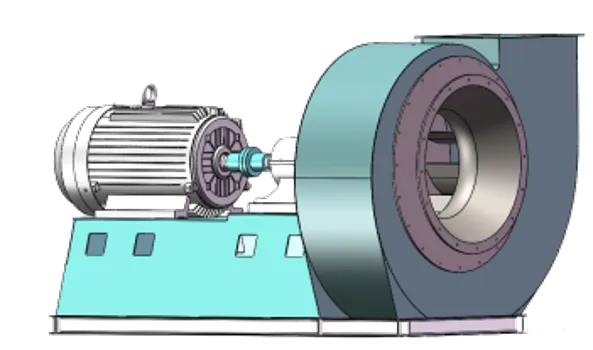

Type A Direct Transmission:

Type D Direct Transmission:

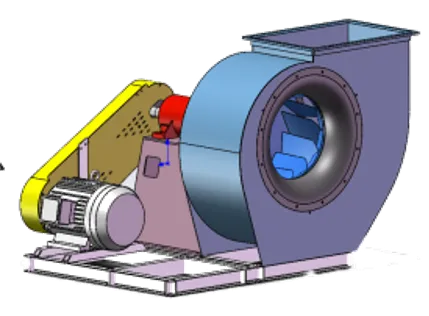

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

Low Pressure Fans:

Low-pressure fan series are 4-72 series, 4-73 series, and 4-79 series. Generally used for indoor ventilation in general factories and large buildings, it can be used as input gas, it can also be used as output gas, it can also be used as output gas, it can also be used for forced ventilation of boilers, forging furnaces, etc.

It is characterized by smooth operation, tight structure, low noise, flexible use, small footprint, high efficiency, and good performance in conveying air and other unnatural, harmless to the human body and non-corrosive gases.

Low-pressure fans are mostly used in garage air supply and exhaust systems, civil air defense ventilation systems, textile exhausts, grain warehouse dry exhausts, and other total air supply and exhaust systems.

Medium Pressure Fans:

The basic models of medium-pressure fans are 5-51 series, 6-51 series, 5-47/5-48 series, and 6-41 series. These models’ air volume and pressure are lower than those of the low-pressure series. Good aerodynamic performance, high efficiency, low noise, smooth operation.

G, Y6-51 type boiler feed fan is mainly used for 2~670t/h steam in thermal power plants.

The air supply system of the boiler also meets the requirements of the performance parameters of the high-pressure head of the fluidized bed furnace. change

Series fans can also be used for dust removal, mine ventilation, and general ventilation systems.

The blower transports air, and the induced draft fan transports gas containing impurity particles.

When the impurity concentration is less than 200mg/m³, it can be used for over 4 years. If the dust content is too large, the blade should be treated with wear-resistant treatment to extend its service life. G series fans are generally normal temperature; The maximum temperature of Y series induced draft fan shall not exceed 250℃. If more than 250℃. The impeller material should be changed.

High Pressure Fans:

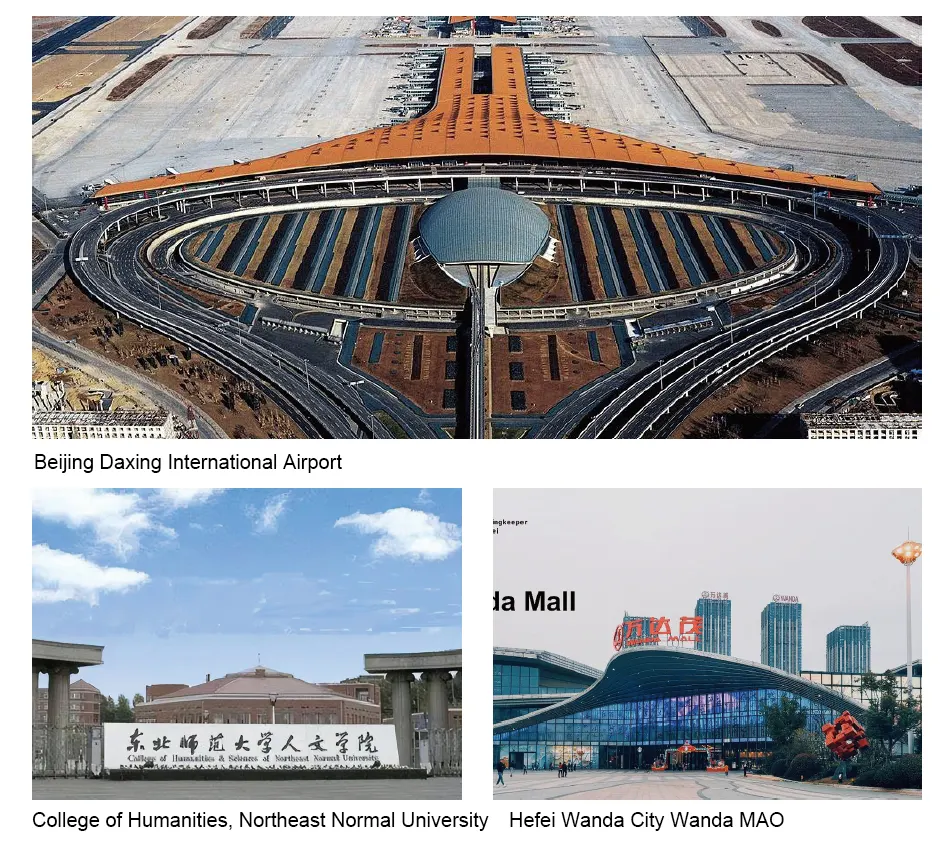

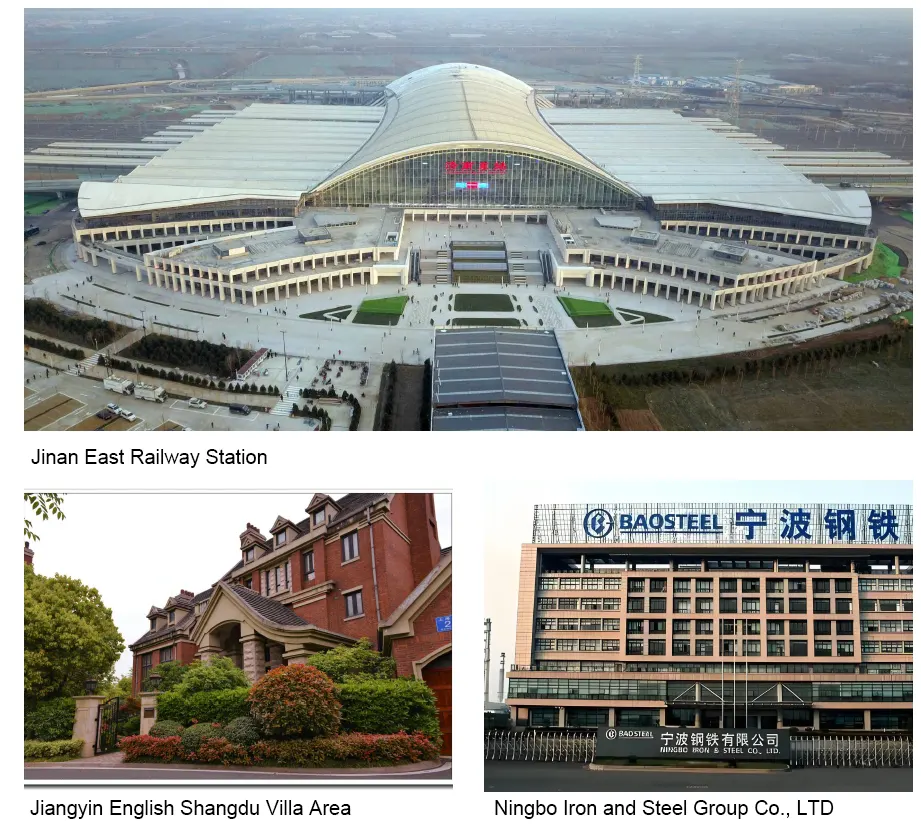

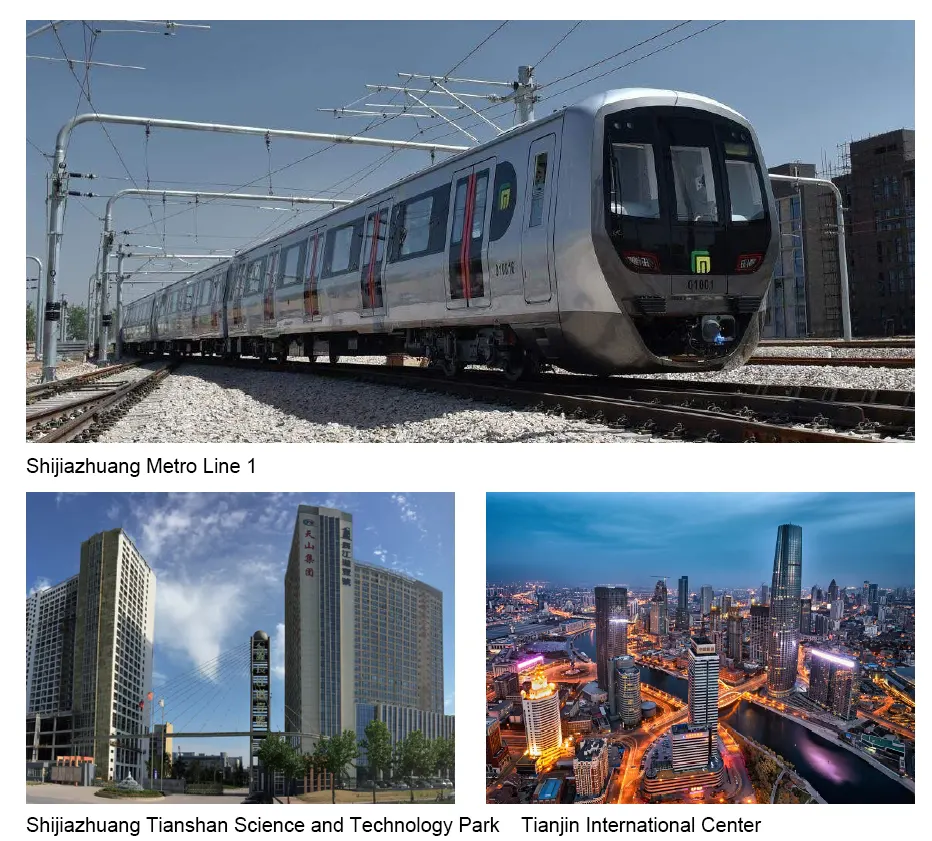

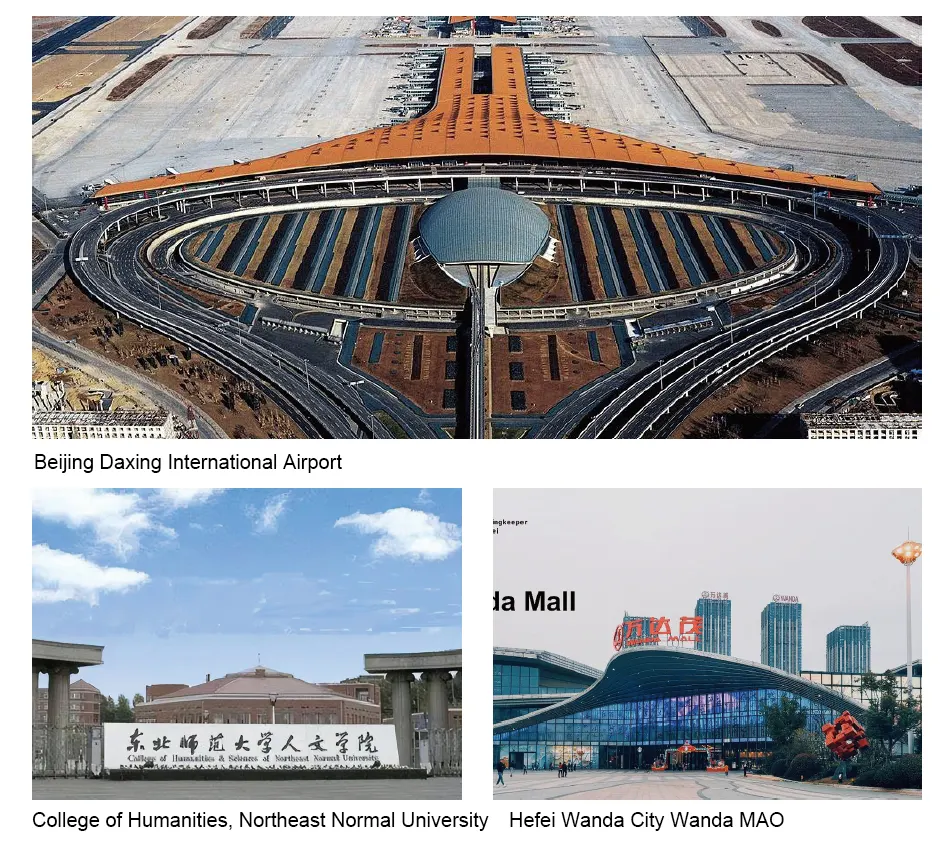

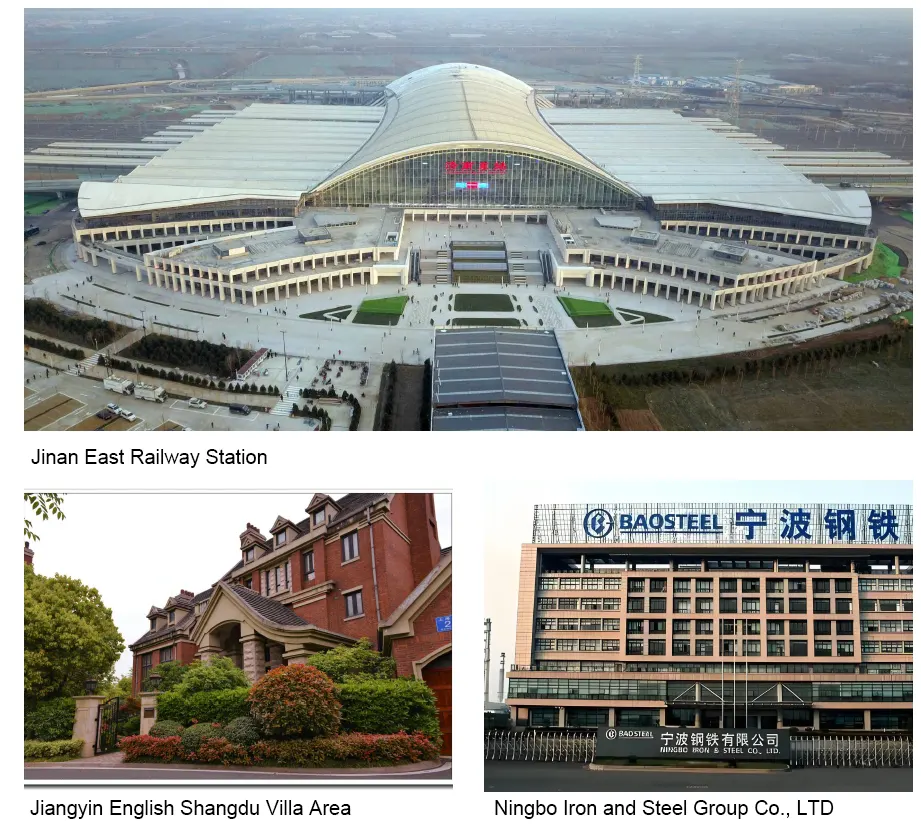

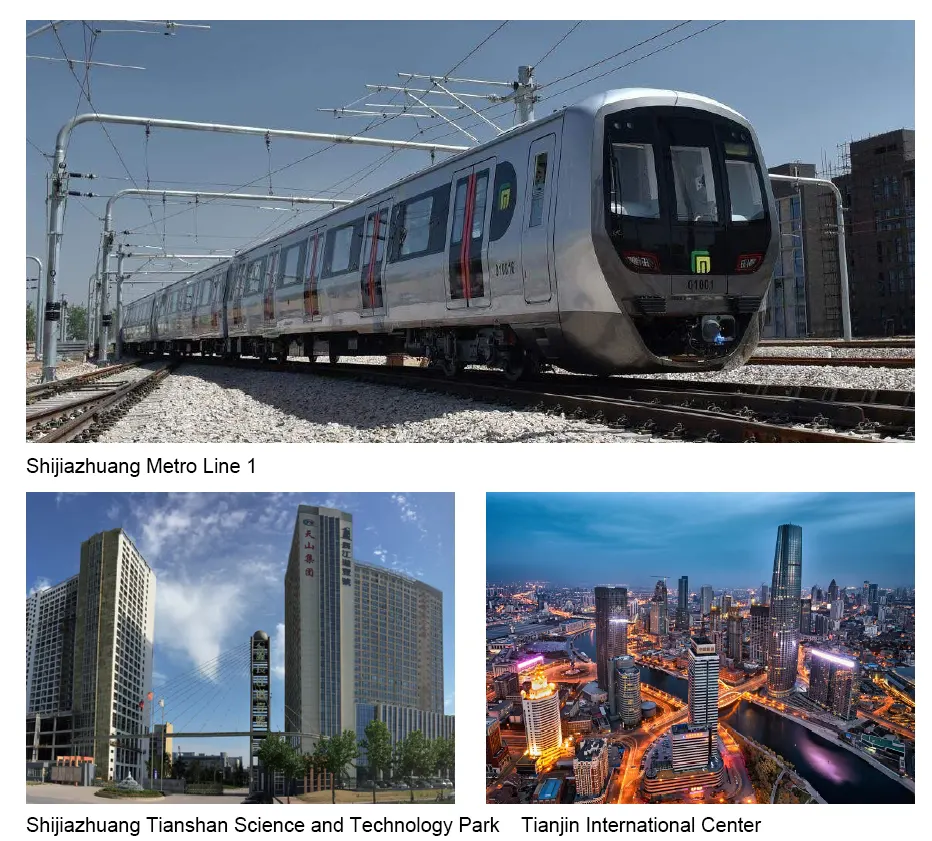

Some Engineering Performance Of The Company:

About Us:

We proudly offer a comprehensive suite of professional services designed to meet the diverse needs of our clients and elevate operational performance. Here’s a closer look at what we provide:

Our Technical Consulting services deliver personalized advice tailored to your specific requirements. Our team of experts assesses your unique challenges and develops strategic solutions that align with your goals, ensuring you receive the guidance necessary for success.

We specialize in Innovative Solutions that introduce strategic approaches to enhance system performance. By leveraging cutting-edge technology and industry best practices, we help you optimize your operations, reduce downtime, and significantly improve overall efficiency.

Our System Operation Support offers expert guidance to ensure seamless operation. Our knowledgeable professionals can assist with troubleshooting, training, and operational best practices, enabling your team to maximize productivity and maintain high-performance levels.

Our Economic Analysis services provide in-depth assessments aimed at maximizing cost-effectiveness. We analyze your systems to identify areas for potential savings and improved return on investment, ensuring that your resources are utilized efficiently.

Our Design Optimization services enhance existing designs for improved efficiency and performance. Our team works closely with you to refine processes, increase reliability, and implement innovative solutions that drive results.

Our commitment to excellence shines through our 24-hour on-site service. We understand that operational challenges can arise anytime, so we provide top-notch maintenance support whenever you need it. Our dedicated team is just a call away, ready to resolve issues promptly and effectively.

We take a proactive approach by establishing detailed user profiles and conducting regular site visits. This allows us to identify potential operational challenges before they become significant, ensuring your systems run smoothly and efficiently.

With our dedicated support, you can experience true peace of mind. We prioritize your success and work tirelessly to ensure that your operations are functional and thriving. Partner with us to unlock the full potential of your systems and drive your business forward. Your success is our mission!