Fire Valve

A Fire Valve is an essential component of fire protection systems, meticulously designed to control water flow within fire sprinkler systems. These valves play a critical role in effective fire suppression, enabling rapid responses during emergencies and helping to protect lives and property. For facility managers, safety personnel, and building owners, it is vital to understand fire valves’ functionality, operation, and maintenance to ensure comprehensive safety.

Fire valves are fundamental to fire protection across various residential, commercial, or industrial settings. By becoming familiar with their essential features and proper usage, you can ensure these systems are primed for action when it matters most.

Investing in high-quality fire valves ensures compliance with safety regulations and offers peace of mind, knowing that you are actively safeguarding lives and property. Make fire safety a priority in your building by implementing dependable fire valve solutions that bolster overall safety and preparedness. Don’t wait for an emergency; take proactive measures to secure your environment today.

Fire Valve Parameter:

Get in Touch for Specific Dimensions

Key Characteristics of Fire Valve:

The Circular Valve is a key player in fluid control systems, distinguished by its remarkable attributes. Here’s a detailed overview of the features that make it an essential asset across various industries:

1. Versatile Applications

The circular valve’s adaptability is evident in its wide range of applications, making it suitable for many industries:

- Water Treatment: It regulates water flow in treatment facilities, ensuring quality and safety.

- Chemical Processing: The valve manages chemical flow in production lines, promoting safe and efficient operations.

- HVAC Systems: It controls airflow in heating and cooling systems, improving comfort and energy efficiency.

2. Robust Durability

Crafted from high-quality materials, the circular valve is designed to endure harsh environments. Its sturdy construction offers resistance to corrosion, wear, and temperature variations, significantly extending its lifespan. This durability leads to fewer replacements and lower maintenance costs, making it a smart long-term investment.

3. Compact Design

The circular valve’s compact size is ideal for installations in restricted spaces. Its ability to fit into tight areas without compromising performance provides greater design flexibility. Whether in a crowded mechanical room or a limited pipeline layout, the circular valve integrates smoothly, ensuring efficient operation.

4. Quick-Response Operation

Engineered for efficiency, the circular valve opens and closes swiftly. This quick response is vital for applications requiring immediate adjustments, allowing operators to react promptly to changes in system demands. Whether addressing pressure fluctuations or flow rate variations, rapid operation keeps processes running smoothly, enhancing productivity and safety.

5. Efficient Flow Management

The circular shape of the valve facilitates smooth and effective fluid flow, significantly reducing pressure drops. This efficiency boosts system performance by allowing fluids to move more freely, leading to lower energy consumption and operational costs. With minimized turbulence and resistance, businesses can achieve improved overall efficiency.

These distinctive features underscore the circular valve’s value in fluid control systems, making it an indispensable tool across multiple industries.

Usage Method of Fire Valve:

Proper maintenance of fire valves is crucial for ensuring their reliable operation and peak performance. Here are some practical guidelines to follow:

Routine Inspections

- Monthly Assessments: Monthly inspections to check for any signs of wear, damage, or corrosion.

- Operational Check: Verify that the valve opens and closes smoothly without any obstructions that might hinder its function.

Cleaning

- Consistent Cleaning: Maintain cleanliness by regularly removing dirt, debris, and any buildup around the valve that could affect its performance.

Testing

- Annual Evaluations: Conduct comprehensive tests each year to assess automatic and manual operation features, ensuring they work correctly.

- Pressure Checks: Perform pressure testing to confirm that the valve maintains the necessary pressure levels.

Professional Servicing

- Yearly Maintenance: Arrange for annual servicing by a qualified technician. This includes detailed inspections, essential adjustments, and replacement of worn components.

By following these maintenance practices, you can significantly improve the reliability and effectiveness of your fire valves, ensuring they function optimally during emergencies.

Fire Valve Application:

Fire valves are essential components in fire protection systems, playing a critical role in various environments. Here’s an overview of their key applications:

1. Commercial Buildings

In office complexes, shopping malls, and hotels, fire valves help manage water flow in sprinkler systems, ensuring effective fire suppression and enhancing occupant safety during emergencies.

2. Industrial Facilities

In manufacturing plants and warehouses, fire valves regulate water supply for fire suppression systems. They protect valuable equipment and materials while ensuring worker safety in high-risk environments.

3. Residential Structures

In multi-family housing, such as apartments and condominiums, fire valves are vital for maintaining effective sprinkler systems, ensuring residents have adequate protection in case of a fire.

4. Healthcare Facilities

Hospitals and clinics rely on fire valves to control water flow in fire suppression systems, safeguarding patient care areas and ensuring rapid response during emergencies.

5. Educational Institutions

Schools, colleges, and universities utilize fire valves to enhance fire safety in classrooms, laboratories, and auditoriums, protecting students and staff during fire incidents.

6. Transportation Hubs

Airports, train stations, and bus terminals incorporate fire valves in their fire protection systems, ensuring passenger safety and maintaining clear evacuation routes during emergencies.

7. Data Centers

In data centers, fire valves are crucial for protecting sensitive electronic equipment from fire hazards, ensuring that fire suppression systems can function effectively without damaging critical infrastructure.

By implementing fire valves in these various applications, organizations can enhance their fire safety measures, ensuring compliance with regulations and safeguarding lives and property.

Fans Type:

General centrifugal fans can be divided into low pressure (P≤1000Pa), medium pressure (P=1000-5000Pa), and high pressure (P=5000-30000Pa) according to the pressure. Low-pressure fans are generally 4-72, 4-73, 4-68, 4-79, and other backward blade series. Medium pressure fans are generally 5-51, 6-30, 6-41, 6-51, and other series; High pressure is generally 9-19, 9-26, 9-12, and 8-09 series. The low-pressure fan blades are mostly backward inclined blades, generally about 45 degrees. The outlet Angle of medium pressure fan is larger than that of low pressure fan. It is generally about 50 degrees, and the blades of the high-pressure fan are generally tilted forward less than 90 degrees. The advantages of medium and low-pressure fans are large flow, low noise value, not easy to overload, relatively stable operation, and use in general ventilation. High-pressure fans are used to supply forced air.

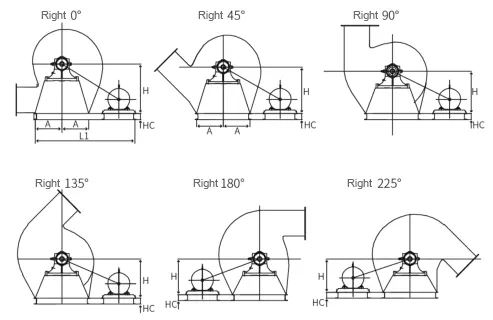

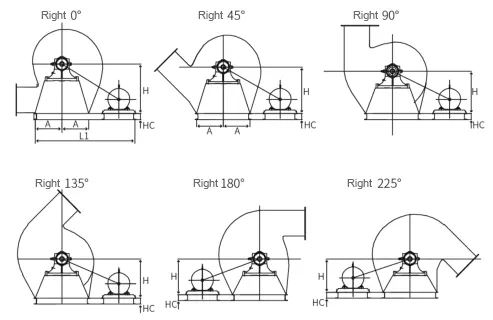

From the direction of the drive side (motor), the counterclockwise rotation is left, and the clockwise rotation is right.

The Angle is generally divided into 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

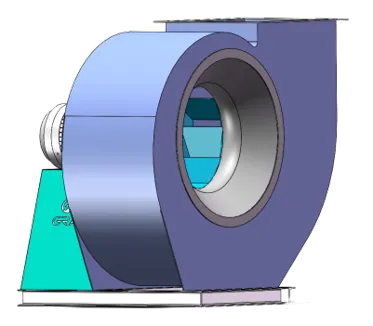

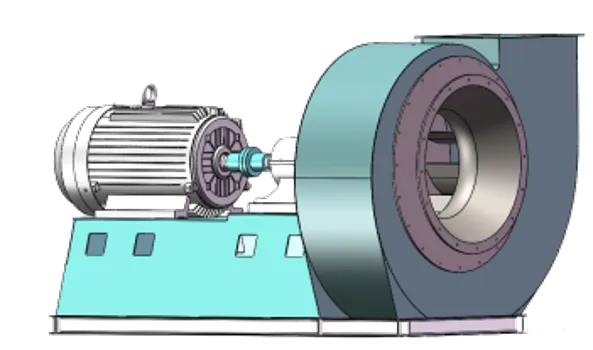

Type A Direct Transmission:

Type D Direct Transmission:

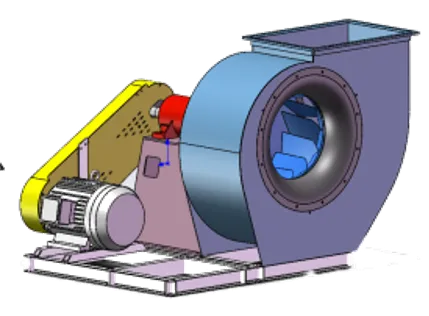

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

Low Pressure Fans:

Low-pressure fan series are 4-72 series, 4-73 series, and 4-79 series. Generally used for indoor ventilation in general factories and large buildings, it can be used as input gas, it can also be used as output gas, it can also be used as output gas, it can also be used for forced ventilation of boilers, forging furnaces, etc.

It is characterized by smooth operation, tight structure, low noise, flexible use, small footprint, high efficiency, and good performance in conveying air and other unnatural, harmless to the human body and non-corrosive gases.

Low-pressure fans are mostly used in garage air supply and exhaust systems, civil air defense ventilation systems, textile exhausts, grain warehouse dry exhausts, and other total air supply and exhaust systems.

Medium Pressure Fans:

The basic models of medium-pressure fans are 5-51 series, 6-51 series, 5-47/5-48 series, and 6-41 series. These models’ air volume and pressure are lower than those of the low-pressure series. Good aerodynamic performance, high efficiency, low noise, smooth operation.

G, Y6-51 type boiler feed fan is mainly used for 2~670t/h steam in thermal power plants.

The air supply system of the boiler also meets the requirements of the performance parameters of the high-pressure head of the fluidized bed furnace. change

Series fans can also be used for dust removal, mine ventilation, and general ventilation systems.

The blower transports air, and the induced draft fan transports gas containing impurity particles.

When the impurity concentration is less than 200mg/m³, it can be used for over 4 years. If the dust content is too large, the blade should be treated with wear-resistant treatment to extend its service life. G series fans are generally normal temperature; The maximum temperature of Y series induced draft fan shall not exceed 250℃. If more than 250℃. The impeller material should be changed.

High Pressure Fans:

Valve Factory:

Our unwavering commitment to excellence encompasses a comprehensive 24/7 on-site service, ensuring you immediate access to top-tier maintenance support whenever needed. We understand that operational efficiency is critical, so our team is always ready to assist you, regardless of the time or day.

Proactive Maintenance Approach

Detailed User Profiles: We take the time to develop thorough user profiles tailored to your specific systems and needs. This personalized approach allows us to understand the intricacies of your operations and tailor our support accordingly.

Regular Site Visits: Our team conducts routine site visits to monitor system performance and identify potential issues before they escalate. This proactive strategy ensures that we address any operational challenges swiftly, minimizing downtime and disruption to your workflow.

Comprehensive Support

Expert Technicians: Our highly trained technicians bring expertise and experience to every interaction, providing you with knowledgeable insights and effective solutions. You can trust that your systems are in capable hands.

Tailored Solutions: We prioritize your unique requirements, offering customized solutions that enhance your system’s performance and reliability. Our goal is to ensure that your operations run seamlessly.

With our dedicated support, you can enjoy peace of mind knowing that your success is our top priority. We are committed to fostering a collaborative partnership, where your needs drive our services. Our responsive support team is always just a call away, ready to assist with any challenges you may encounter.

Experience the difference that our comprehensive, proactive maintenance and exceptional support can make in your operations. Together, we will ensure your systems operate at their best, empowering your success every step of the way!