Galvanized Steel Smoke Exhaust Fire Valve

The Galvanized Steel Smoke Exhaust Fire Valve is a crucial component of fire safety systems, specifically engineered to manage smoke and heat during emergencies. Made from high-quality galvanized steel, this valve boasts remarkable durability and corrosion resistance, making it suitable for various environments, including commercial buildings, industrial sites, and residential properties. Its primary purpose is to facilitate the safe and efficient removal of smoke and hot gases, thereby protecting occupants and minimizing damage to property.

The importance of this valve in fire safety cannot be emphasized enough. With its robust construction, capability to withstand high temperatures, and effective smoke control features, the Galvanized Steel Smoke Exhaust Fire Valve is a key investment for any facility. When properly installed and maintained, it functions reliably during critical situations, playing a vital role in protecting lives and property.

Enhance your building’s fire protection strategy by equipping it with this essential safety device. The Galvanized Steel Smoke Exhaust Fire Valve allows you to take proactive measures in ensuring a safer environment for all occupants.

Galvanized Steel Smoke Exhaust Fire Valve Parameter:

Get in Touch for Specific Dimensions

Key Characteristics of Galvanized Steel Smoke Exhaust Fire Valve:

Sturdy Build

Constructed from premium galvanized steel, the Galvanized Steel Smoke Exhaust Fire Valve is designed to withstand even the most demanding conditions. Its strong structure resists rust and corrosion and guarantees long-lasting reliability. This durability ensures that the valve will perform effectively year after year, giving you confidence during critical situations.

Exceptional Heat Resistance

This valve is precisely engineered to endure extreme temperatures, maintaining its functionality and integrity during fire emergencies. Its remarkable heat tolerance allows it to operate effectively, even when exposed to the intense heat generated by flames. This feature is crucial for ensuring safety and efficiency in emergency scenarios.

Effective Smoke Management

The valve efficiently channels smoke to designated exhaust points, significantly improving air quality and safety during a fire. By managing smoke movement effectively, it protects occupants from harmful fumes and reduces the risk of smoke inhalation. This efficient smoke control helps create safer escape routes during emergencies.

Flexible Installation

Thanks to its lightweight design, this valve is easy to install across various duct systems. Its versatility minimizes installation time and costs, making it an excellent choice for both new projects and retrofitting existing systems. Quick and straightforward installation ensures that your fire safety measures are implemented without unnecessary delays.

Manual and Automated Functionality

The Galvanized Steel Smoke Exhaust Fire Valve comes in both manual and automatic versions, accommodating a range of fire safety protocols and preferences. This flexibility allows you to select the option that best suits your facility, whether you prefer direct control or automated operation linked to your fire alarm system. Regardless of your choice, you can trust that it will fulfill your specific safety needs.

With these outstanding features, the Galvanized Steel Smoke Exhaust Fire Valve is a reliable and efficient solution for enhancing fire safety. Its robust construction, exceptional heat resistance, effective smoke management, flexible installation, and versatile operation make it an essential investment for any building aiming to strengthen its fire protection strategy.

Usage Method of Galvanized Steel Smoke Exhaust Fire Valve:

Step 1: Choose the Installation Location

- Identify an Optimal Spot: Locate a flat and unobstructed area on the roof that promotes optimal airflow for the fan. This helps ensure it operates efficiently.

- Avoid Obstructions: Position the fan away from nearby structures, such as walls, chimneys, or other obstacles, that could impede airflow and reduce performance.

Step 2: Securely Mount the Fan

- Firm Attachment: Utilize the supplied brackets and screws to affix the fan to the roof securely. This step is crucial for maintaining stability and performance.

- Verify Level Placement: Ensure that the fan is installed level. An even installation is key to maximizing airflow efficiency and preventing operational issues.

Step 3: Connect the Electrical Wiring

- Adhere to Manufacturer Guidelines: Follow the manufacturer’s detailed instructions for making electrical connections, ensuring that all work complies with local electrical codes and regulations.

- Conduct a Safety Inspection: Carefully review all connections before powering on the fan. This precaution helps prevent any potential electrical hazards.

Step 4: Power On the Fan

- Activate the Fan: Once installation is complete and all electrical connections have been verified, power on the fan. Adjust the speed settings based on your specific ventilation needs.

- Monitor Performance: Observe the airflow to ensure it meets your expectations for adequate ventilation. Regular monitoring can help you identify any issues early and maintain optimal performance.

By following these comprehensive steps, you can ensure a successful fan installation, maximizing its efficiency and effectiveness in improving your indoor environment.

Galvanized Steel Smoke Exhaust Fire Valve Application:

The Galvanized Steel Smoke Exhaust Fire Valve plays a crucial role in various environments, significantly improving fire safety and smoke management. Here are some notable applications:

1. Healthcare Facilities

- Hospitals: Ensures efficient smoke control in critical care areas, safeguarding both patients and staff during emergencies.

- Nursing Homes: Creates a safer living environment for vulnerable residents by providing clear evacuation routes in the event of a fire.

2. Residential Properties

- Multi-Story Apartments: Facilitates smoke exhaust in hallways and stairwells, ensuring safe egress for residents during fire incidents.

- Single-Family Homes: Improves fire safety, especially in homes with intricate HVAC systems, by managing smoke effectively.

3. Educational Institutions

- Schools and Universities: Strengthens fire safety measures in classrooms and common areas, prioritizing the safety of students and staff during emergency situations.

- Libraries and Laboratories: Manages smoke efficiently to protect valuable resources and ensure safe escape paths during a fire.

4. Commercial Buildings

- Office Spaces: Provides essential smoke ventilation, enhancing safety for employees and visitors in the event of a fire.

- Shopping Malls: Controls smoke and heat in large retail environments, protecting occupants and minimizing potential property damage.

5. Industrial Facilities

- Manufacturing Plants: Effectively removes smoke and fumes, ensuring a safer working environment and compliance with safety regulations.

- Warehouses: Delivers crucial smoke control in expansive areas, preventing heat accumulation and safeguarding stored inventory.

6. Agricultural Settings

- Greenhouses: Regulates temperature and air quality to prevent heat stress on plants, optimizing growth conditions for better yields.

- Livestock Facilities: Ensures adequate ventilation, promoting animal welfare and improving living conditions for livestock.

These diverse applications highlight the importance of the Galvanized Steel Smoke Exhaust Fire Valve in enhancing fire safety and smoke management across various settings.

Fans Type:

General centrifugal fans can be divided into low pressure (P≤1000Pa), medium pressure (P=1000-5000Pa), and high pressure (P=5000-30000Pa) according to the pressure. Low-pressure fans are generally 4-72, 4-73, 4-68, 4-79, and other backward blade series. Medium pressure fans are generally 5-51, 6-30, 6-41, 6-51, and other series; High pressure is generally 9-19, 9-26, 9-12, and 8-09 series. The low-pressure fan blades are mostly backward inclined blades, generally about 45 degrees. The outlet Angle of medium pressure fan is larger than that of low pressure fan. It is generally about 50 degrees, and the blades of the high-pressure fan are generally tilted forward less than 90 degrees. The advantages of medium and low-pressure fans are large flow, low noise value, not easy to overload, relatively stable operation, and use in general ventilation. High-pressure fans are used to supply forced air.

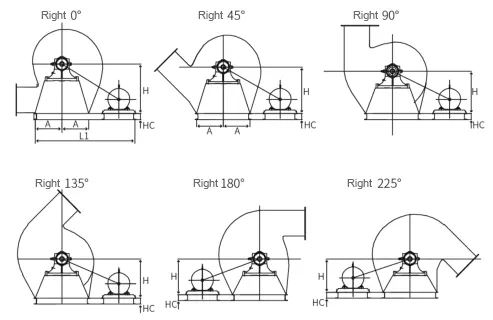

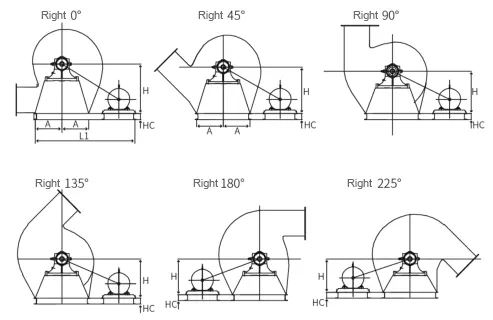

From the direction of the drive side (motor), the counterclockwise rotation is left, and the clockwise rotation is right.

The Angle is generally divided into 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

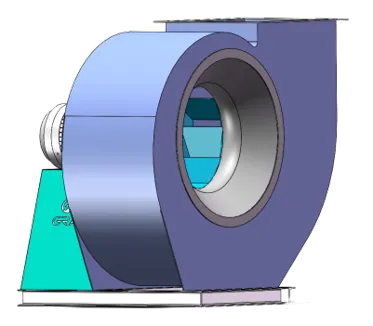

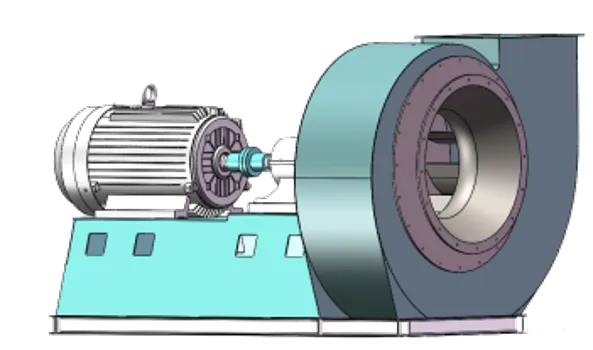

Type A Direct Transmission:

Type D Direct Transmission:

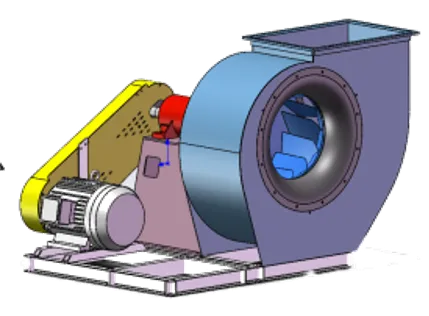

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

Low Pressure Fans:

Low-pressure fan series are 4-72 series, 4-73 series, and 4-79 series. Generally used for indoor ventilation in general factories and large buildings, it can be used as input gas, it can also be used as output gas, it can also be used as output gas, it can also be used for forced ventilation of boilers, forging furnaces, etc.

It is characterized by smooth operation, tight structure, low noise, flexible use, small footprint, high efficiency, and good performance in conveying air and other unnatural, harmless to the human body and non-corrosive gases.

Low-pressure fans are mostly used in garage air supply and exhaust systems, civil air defense ventilation systems, textile exhausts, grain warehouse dry exhausts, and other total air supply and exhaust systems.

Medium Pressure Fans:

The basic models of medium-pressure fans are 5-51 series, 6-51 series, 5-47/5-48 series, and 6-41 series. These models’ air volume and pressure are lower than those of the low-pressure series. Good aerodynamic performance, high efficiency, low noise, smooth operation.

G, Y6-51 type boiler feed fan is mainly used for 2~670t/h steam in thermal power plants.

The air supply system of the boiler also meets the requirements of the performance parameters of the high-pressure head of the fluidized bed furnace. change

Series fans can also be used for dust removal, mine ventilation, and general ventilation systems.

The blower transports air, and the induced draft fan transports gas containing impurity particles.

When the impurity concentration is less than 200mg/m³, it can be used for over 4 years. If the dust content is too large, the blade should be treated with wear-resistant treatment to extend its service life. G series fans are generally normal temperature; The maximum temperature of Y series induced draft fan shall not exceed 250℃. If more than 250℃. The impeller material should be changed.

High Pressure Fans:

Valve Factory:

Our unwavering commitment to excellence encompasses a comprehensive 24/7 on-site service, ensuring that you have immediate access to top-tier maintenance support whenever you need it. We understand that operational efficiency is critical, which is why our team is always ready to assist you, regardless of the time or day.

Proactive Maintenance Approach

Detailed User Profiles: We take the time to develop thorough user profiles tailored to your specific systems and needs. This personalized approach allows us to understand the intricacies of your operations and tailor our support accordingly.

Regular Site Visits: Our team conducts routine site visits to monitor system performance and identify potential issues before they escalate. This proactive strategy ensures that we address any operational challenges swiftly, minimizing downtime and disruption to your workflow.

Comprehensive Support

Expert Technicians: Our highly trained technicians bring expertise and experience to every interaction, providing you with knowledgeable insights and effective solutions. You can trust that your systems are in capable hands.

Tailored Solutions: We prioritize your unique requirements, offering customized solutions that enhance your system’s performance and reliability. Our goal is to ensure that your operations run seamlessly.

With our dedicated support, you can enjoy peace of mind knowing that your success is our top priority. We are committed to fostering a collaborative partnership, where your needs drive our services. Our responsive support team is always just a call away, ready to assist with any challenges you may encounter.

Experience the difference that our comprehensive, proactive maintenance and exceptional support can make in your operations. Together, we will ensure your systems operate at their best, empowering your success every step of the way!