Single Layer Louvered Vent

The Single Layer Louvered Vent is a vital component for ensuring effective airflow in a variety of building applications. Engineered to provide optimal ventilation while preventing water intrusion, this vent is suitable for both residential and commercial environments. Its simple yet effective design has made it a favored option among architects and builders focused on improving indoor air quality.

This vent is an ideal solution for anyone looking to enhance ventilation in their space. With its efficient airflow, durable construction, and aesthetic adaptability, it serves as a reliable choice for multiple applications. By adhering to the installation and maintenance guidelines, you can maximize the vent’s performance, fostering a healthier indoor environment and safeguarding your property from moisture-related issues. Make a smart investment in your ventilation needs by choosing the Single Layer Louvered Vent today.

Single Layer Louvered Vent Parameter:

Contact Us For Detailed Dimensions

Key Characteristics of Single Layer Louvered Vent:

The Single Layer Louvered Vent is expertly designed to deliver efficient ventilation while combining durability with aesthetic appeal. Here’s a closer look at its key features:

Effective Airflow

- Optimized Louver Design: The louvered configuration enhances airflow, allowing fresh air to circulate freely throughout the space. This design helps maintain a consistent and comfortable indoor environment by preventing air stagnation.

- Water Intrusion Prevention: The strategic angle of the louvers significantly reduces the risk of water entering your home while still promoting effective ventilation. This feature is particularly important in moisture-prone areas, helping to guard against mold and mildew growth.

Durable Construction

- High-Quality Materials: Made from robust, weather-resistant materials, the Single Layer Louvered Vent is designed to endure harsh environmental conditions, including extreme temperatures, heavy rainfall, and intense sunlight.

- Long-Lasting Performance: Its durable construction ensures the vent remains functional and effective over time, minimizing the need for frequent replacements and maintenance.

Versatile Applications

- Adaptable Installation: Suitable for various locations within a building—such as attics, basements, and crawl spaces—this vent is an ideal choice for meeting diverse ventilation needs.

- Multi-Functional Use: Whether enhancing airflow in residential spaces or improving ventilation in commercial settings, this vent adapts effectively to specific requirements.

Aesthetic Options

- Variety of Colors and Finishes: The Single Layer Louvered Vent is available in multiple styles, allowing customization to match your building’s exterior. This variety enables homeowners and builders to select options that align with their design preferences.

- Seamless Integration: Its aesthetic flexibility ensures that the vent enhances the overall appearance of your property, boosting visual appeal without compromising functionality.

The Single Layer Louvered Vent is an outstanding solution for enhancing ventilation in any building. With its effective airflow, robust construction, versatile applications, and customizable aesthetic options, it improves indoor air quality while adding value and appeal to your space. Investing in this vent guarantees a healthier and more comfortable environment, along with long-lasting performance and reliability.

Usage Method of Single Layer Louvered Vent:

Installing a single-layer louvered vent is an effective way to improve your home’s ventilation. Proper installation not only optimizes airflow but also protects against moisture intrusion. Follow these detailed steps for a successful installation:

1. Select the Location

- Assess Ventilation Needs: Identify areas in your home that would benefit from improved ventilation, such as attics, crawl spaces, or basements. These spaces often require enhanced airflow to reduce humidity levels and prevent mold growth.

- Check for Obstructions: Ensure the chosen location allows for unobstructed airflow. Avoid spots blocked by insulation, beams, or other structural elements that could hinder performance.

2. Measure and Mark

- Take Accurate Measurements: Carefully measure the vent’s dimensions, noting its width and height. Use a tape measure for precision.

- Mark the Opening: Use a pencil to outline the corresponding opening on the wall or ceiling where the vent will be installed. Double-check your measurements to ensure accuracy.

3. Cut the Opening

- Choose the Right Tools: Use a jigsaw or reciprocating saw for cutting. Make sure you have the appropriate blades for the material you’re working with (e.g., wood, drywall).

- Cut with Care: Follow your marked lines and cut the opening to match the size of the vent. Take your time to ensure clean, straight edges for a snug fit.

4. Install the Vent

- Position the Vent: Insert the vent into the opening, ensuring it sits flush against the surface. Verify that it aligns properly, with the louvers positioned to facilitate optimal airflow.

- Secure the Vent: Follow the manufacturer’s guidelines to attach the vent using screws or adhesive. If using screws, ensure they are suitable for the wall material for a tight fit.

5. Seal the Edges

- Apply Weatherproof Caulking: To prevent water intrusion, apply a generous bead of weatherproof caulk around the edges of the vent. This will enhance the vent’s resistance to moisture and drafts.

- Smooth the Caulk: Use a caulking tool or your finger to smooth the caulk for a neat finish. Ensure there are no gaps or air pockets, as these can compromise the vent’s effectiveness.

6. Final Checks

- Inspect the Installation: Once the vent is installed and sealed, conduct a final inspection. Ensure that the vent opens and closes smoothly, with no visible gaps.

- Test Airflow: Check that air circulates freely through the vent, confirming that it functions as intended.

By following these steps, you can successfully install a single-layer louvered vent, enhancing ventilation and protecting your home from moisture-related issues.

Single Layer Louvered Vent Application:

The Single Layer Louvered Vent is a versatile ventilation solution suitable for a wide range of environments. Its thoughtful design and functionality enhance airflow and contribute to improved indoor air quality. Here are some of its key applications:

1. Attics

- Moisture Control: Proper ventilation is essential in attics to prevent moisture buildup, which can lead to mold growth and structural damage. The Single Layer Louvered Vent facilitates airflow, allowing hot, humid air to escape effectively.

- Temperature Regulation: Effective attic ventilation helps manage temperature, reducing heat accumulation during summer months and improving the energy efficiency of cooling systems.

2. Basements

- Humidity Reduction: Basements often struggle with high humidity levels, making them susceptible to mold. Installing louvered vents promotes air circulation, reducing humidity and fostering a healthier environment.

- Improved Air Quality: These vents allow fresh air to enter while expelling stale air, significantly enhancing indoor air quality and making basements more comfortable for living or storage.

3. Crawl Spaces

- Ventilation Enhancement: Crawl spaces can trap moisture and pollutants. The Single Layer Louvered Vent provides essential airflow, helping to keep these areas dry and preventing mold and pest infestations.

- Energy Efficiency: Proper ventilation in crawl spaces enhances the overall energy efficiency of a home, alleviating strain on HVAC systems and reducing energy costs.

4. Commercial Buildings

- Industrial Applications: In warehouses and industrial settings, louvered vents effectively exhaust hot air and improve ventilation, creating a safer and more comfortable working environment.

- Retail Spaces: Retail environments benefit from enhanced air circulation, with these vents helping to maintain a pleasant atmosphere for both customers and employees.

5. Residential Homes

- General Ventilation: The Single Layer Louvered Vent can be utilized in various areas of a home, such as garages, laundry rooms, and utility spaces, enhancing airflow and preventing stagnant air.

- Aesthetic Functionality: Available in a variety of designs, these vents can seamlessly integrate into the architectural style of a home, providing both functionality and visual appeal.

The Single Layer Louvered Vent is adaptable to numerous applications, making it an essential component for effective ventilation in both residential and commercial settings. By addressing moisture control, improving air quality, and enhancing energy efficiency, this vent serves as a reliable solution for maintaining a healthy indoor environment. Whether in attics, basements, crawl spaces, or commercial buildings, the Single Layer Louvered Vent plays a crucial role in enhancing airflow and overall comfort.

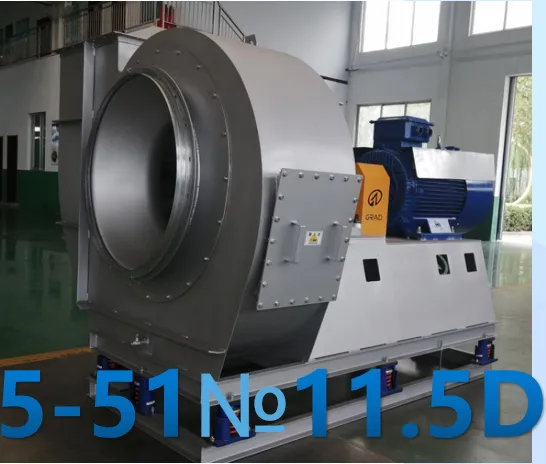

Fans Type:

General centrifugal fans can be divided into low pressure (P≤1000Pa), medium pressure (P=1000-5000Pa), and high pressure (P=5000-30000Pa) according to the pressure. Low-pressure fans are generally 4-72, 4-73, 4-68, 4-79, and other backward blade series. Medium pressure fans are generally 5-51, 6-30, 6-41, 6-51, and other series; High pressure is generally 9-19, 9-26, 9-12, and 8-09 series. The low-pressure fan blades are mostly backward inclined blades, generally about 45 degrees. The outlet Angle of medium pressure fan is larger than that of low pressure fan. It is generally about 50 degrees, and the blades of the high-pressure fan are generally tilted forward less than 90 degrees. The advantages of medium and low-pressure fans are large flow, low noise value, not easy to overload, relatively stable operation, and use in general ventilation. High-pressure fans are used to supply forced air.

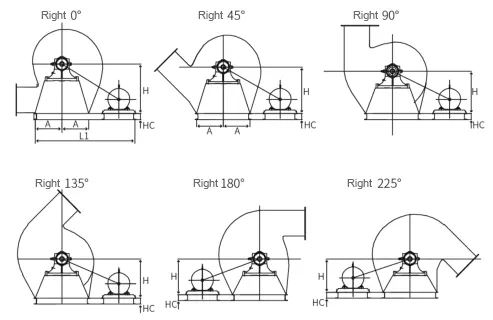

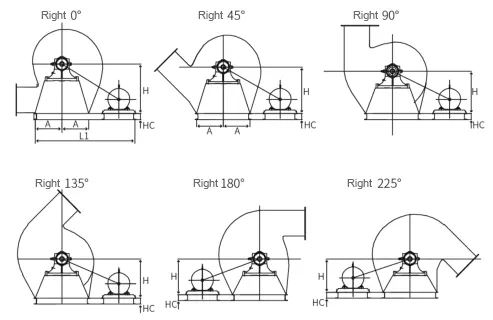

From the direction of the drive side (motor), the counterclockwise rotation is left, and the clockwise rotation is right.

The Angle is generally divided into 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

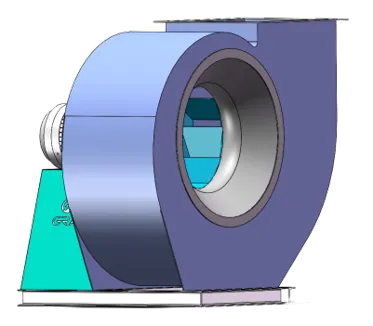

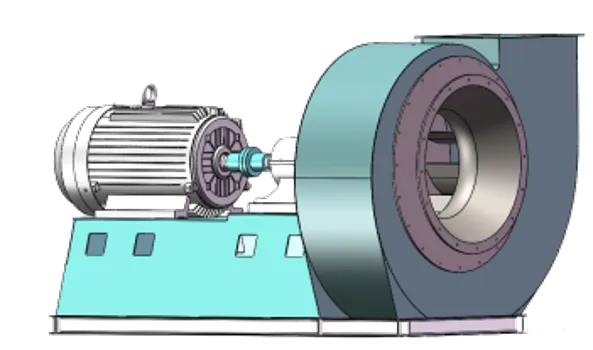

Type A Direct Transmission:

Type D Direct Transmission:

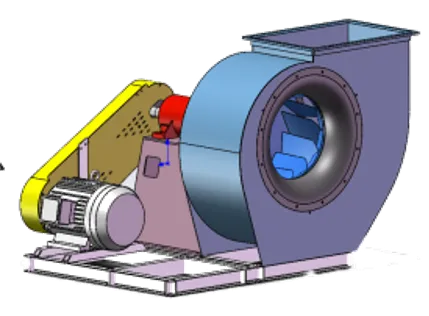

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

Low Pressure Fans:

Low-pressure fan series are 4-72 series, 4-73 series, and 4-79 series. Generally used for indoor ventilation in general factories and large buildings, it can be used as input gas, it can also be used as output gas, it can also be used as output gas, it can also be used for forced ventilation of boilers, forging furnaces, etc.

It is characterized by smooth operation, tight structure, low noise, flexible use, small footprint, high efficiency, and good performance in conveying air and other unnatural, harmless to the human body and non-corrosive gases.

Low-pressure fans are mostly used in garage air supply and exhaust systems, civil air defense ventilation systems, textile exhausts, grain warehouse dry exhausts, and other total air supply and exhaust systems.

Medium Pressure Fans:

The basic models of medium-pressure fans are 5-51 series, 6-51 series, 5-47/5-48 series, and 6-41 series. These models’ air volume and pressure are lower than those of the low-pressure series. Good aerodynamic performance, high efficiency, low noise, smooth operation.

G, Y6-51 type boiler feed fan is mainly used for 2~670t/h steam in thermal power plants.

The air supply system of the boiler also meets the requirements of the performance parameters of the high-pressure head of the fluidized bed furnace. change

Series fans can also be used for dust removal, mine ventilation, and general ventilation systems.

The blower transports air, and the induced draft fan transports gas containing impurity particles.

When the impurity concentration is less than 200mg/m³, it can be used for over 4 years. If the dust content is too large, the blade should be treated with wear-resistant treatment to extend its service life. G series fans are generally normal temperature; The maximum temperature of Y series induced draft fan shall not exceed 250℃. If more than 250℃. The impeller material should be changed.

High Pressure Fans:

Valve Factory:

Our unwavering commitment to excellence encompasses a comprehensive 24/7 on-site service, ensuring you immediate access to top-tier maintenance support whenever needed. We understand that operational efficiency is critical, so our team is always ready to assist you, regardless of the time or day.

Proactive Maintenance Approach

Detailed User Profiles: We take the time to develop thorough user profiles tailored to your specific systems and needs. This personalized approach allows us to understand the intricacies of your operations and tailor our support accordingly.

Regular Site Visits: Our team conducts routine site visits to monitor system performance and identify potential issues before they escalate. This proactive strategy ensures that we address any operational challenges swiftly, minimizing downtime and disruption to your workflow.

Comprehensive Support

Expert Technicians: Our highly trained technicians bring expertise and experience to every interaction, providing you with knowledgeable insights and effective solutions. You can trust that your systems are in capable hands.

Tailored Solutions: We prioritize your unique requirements, offering customized solutions that enhance your system’s performance and reliability. Our goal is to ensure that your operations run seamlessly.

With our dedicated support, you can enjoy peace of mind knowing that your success is our top priority. We are committed to fostering a collaborative partnership, where your needs drive our services. Our responsive support team is always just a call away, ready to assist with any challenges you may encounter.

Experience the difference that our comprehensive, proactive maintenance and exceptional support can make in your operations. Together, we will ensure your systems operate at their best, empowering your success every step of the way!