Stainless Steel Duct

The Stainless Steel Duct stands out as a premier option for HVAC systems, celebrated for its exceptional strength and performance. Constructed from high-quality stainless steel, this duct is designed to withstand even the most challenging environments while ensuring optimal air distribution. Its sleek and contemporary design, combined with durable construction, makes it suitable for both residential and commercial applications.

This duct offers an excellent combination of reliability and visual appeal, making it highly effective for air management in various settings. With outstanding corrosion resistance, customizable configurations, and a user-friendly installation process, it is the perfect choice for any project. By opting for stainless steel ducts, you enhance the efficiency of your HVAC system and foster a comfortable and healthy environment for all occupants. Choose quality and experience the benefits!

Stainless Steel Duct Parameter:

Get in Touch for Specific Dimensions

Key Characteristics of Stainless Steel Duct:

- Versatile Design

Stainless steel ducts are available in a wide range of sizes and configurations, allowing for tailored solutions that meet specific airflow requirements. Whether you’re outfitting a compact space or a large facility, these ducts can be customized to ensure optimal efficiency and performance. - Sleek Appearance

The polished surface of stainless steel not only provides durability but also enhances the aesthetic appeal of any installation. This modern look makes it perfect for visible applications, seamlessly integrating with both residential and commercial designs. Stainless steel ducts elevate the overall appearance of your HVAC system. - Superior Resistance

Known for its remarkable resistance to rust and corrosion, stainless steel is particularly suitable for environments exposed to moisture or chemicals. This inherent strength helps maintain the duct’s integrity and performance over time, minimizing the need for replacements and repairs. - Robust Construction

Built to withstand high temperatures and heavy-duty use, stainless steel ducts excel in demanding conditions. Their sturdy design ensures they maintain shape and functionality, even under constant airflow. This reliability makes them ideal for both industrial and residential applications. - Efficient Installation

Engineered for lightweight and efficient assembly, stainless steel ducts simplify the installation process. Their design allows for quick connections and adjustments, which saves time and reduces labor costs. You can quickly enjoy the benefits of your HVAC system without compromising on quality.

The combination of versatile design, sleek appearance, superior resistance, robust construction, and efficient installation makes stainless steel ducts an excellent choice for any air management system. By opting for these high-quality ducts, you ensure lasting performance, improved indoor air quality, and a visually appealing setup tailored to your needs. Discover the benefits of stainless steel ducts and enhance your HVAC system today!

Usage Method of Stainless Steel Duct:

- Planning

Begin by conducting a comprehensive assessment of the installation area. This essential first step involves mapping out the ideal duct layout tailored to your HVAC requirements. Take precise measurements to ensure the duct fits seamlessly within the designated space. Consider airflow direction and any potential obstacles, which will facilitate a smoother installation process. - Cutting

If any adjustments are necessary, use specialized tools like tin snips or a metal saw to cut the stainless steel duct to the required lengths. Make sure your cuts are clean and accurate, as this attention to detail is critical for maintaining proper airflow and preventing turbulence within the duct system. - Connecting

After cutting the ducts to the correct size, align the sections carefully. Secure them using high-quality stainless steel screws or clamps to ensure a tight fit and eliminate air leaks. This step is vital for maintaining system efficiency, as well-connected ducts reduce energy loss and enhance overall performance, resulting in lower utility costs. - Sealing

Once the duct sections are connected, apply a premium sealant around all joints. This high-quality sealant is crucial for boosting energy efficiency by preventing air leaks. Proper sealing enhances performance and extends the lifespan of your HVAC system by reducing strain on the equipment.

Operational Use

After installation, the Stainless Steel Duct effectively channels air throughout your space. Its smooth interior design minimizes friction, promoting optimal airflow. This thoughtful construction helps maintain consistent temperatures across various rooms, ensuring a comfortable environment.

Additionally, adequate ventilation enhances indoor air quality by expelling stale air and circulating fresh air. This is particularly important in residential settings, where air quality significantly impacts health and well-being. In commercial spaces, efficient air management contributes to employee productivity and customer comfort.

By choosing stainless steel ducts, you ensure superior airflow and foster a healthier, more welcoming atmosphere for everyone. Experience the advantages of a well-installed duct system and enjoy the confidence of optimized HVAC performance!

Stainless Steel Duct Application:

Stainless steel ducts are both versatile and durable, making them ideal for a wide range of applications. Here’s a detailed overview of their standout uses:

Industrial Settings

Manufacturing facilities benefit from stainless steel ducts designed to withstand heavy usage, efficiently managing air circulation and effectively removing heat and fumes generated by machinery. In chemical processing plants, their corrosion-resistant properties make them perfect for environments dealing with corrosive substances, ensuring safety and durability.

Healthcare Environments

In hospitals, these ducts are crucial in delivering clean, filtered air to patient rooms and surgical theaters, helping maintain a sterile atmosphere. They are also essential in laboratories, where they vent harmful fumes and ensure proper airflow, safeguarding personnel’s health and research activities’ integrity.

Commercial Spaces

Office buildings utilize stainless steel ducts to provide optimal airflow in open-plan environments, enhancing employee comfort and productivity. Retail spaces benefit from these ducts as they regulate temperature and air quality, creating a pleasant shopping experience for customers.

Residential Applications

In HVAC systems, stainless steel ducts efficiently distribute cooled air throughout homes, ensuring comfort during warm weather. They are also ideal for delivering warm air from furnaces, helping maintain consistent indoor temperatures and improving energy efficiency. Additionally, these ducts are used in exhaust systems for kitchens and bathrooms, eliminating humidity and odors to enhance indoor air quality.

Food and Beverage Sector

In food processing plants, stainless steel ducts are vital for managing air quality and temperature in environments where hygiene is critical. Restaurants also benefit from these ducts, as they effectively remove smoke and odors from kitchens, providing a comfortable dining experience for customers.

Data Centers

In cooling systems, stainless steel ducts play a key role in cooling servers and critical equipment, preventing overheating and ensuring optimal performance.

Transportation Hubs

Airports and train stations utilize these ducts to manage airflow in busy terminals, ensuring passenger comfort and air quality in high-traffic areas.

Choosing stainless steel ducts enhances air management and contributes to safety and efficiency across diverse applications.

Fans Type:

General centrifugal fans can be divided into low pressure (P≤1000Pa), medium pressure (P=1000-5000Pa), and high pressure (P=5000-30000Pa) according to the pressure. Low-pressure fans are generally 4-72, 4-73, 4-68, 4-79, and other backward blade series. Medium pressure fans are generally 5-51, 6-30, 6-41, 6-51, and other series; High pressure is generally 9-19, 9-26, 9-12, and 8-09 series. The low-pressure fan blades are mostly backward inclined blades, generally about 45 degrees. The outlet Angle of medium pressure fan is larger than that of low pressure fan. It is generally about 50 degrees, and the blades of the high-pressure fan are generally tilted forward less than 90 degrees. The advantages of medium and low-pressure fans are large flow, low noise value, not easy to overload, relatively stable operation, and use in general ventilation. High-pressure fans are used to supply forced air.

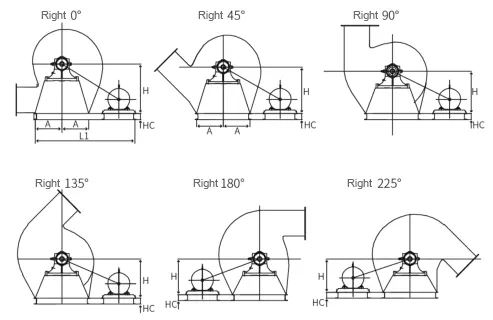

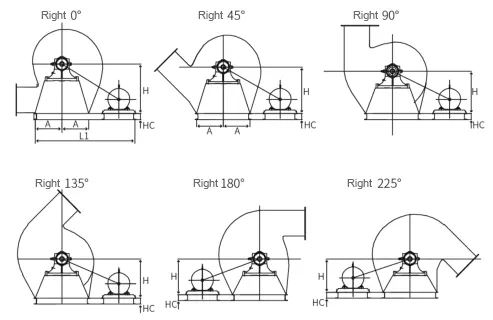

From the direction of the drive side (motor), the counterclockwise rotation is left, and the clockwise rotation is right.

The Angle is generally divided into 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

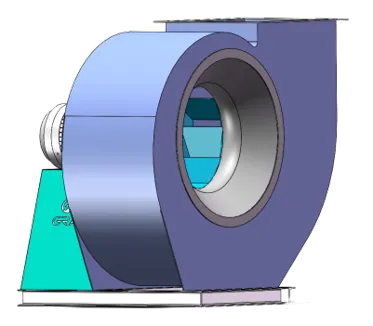

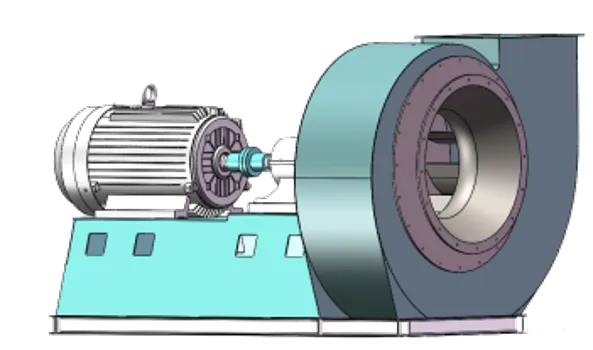

Type A Direct Transmission:

Type D Direct Transmission:

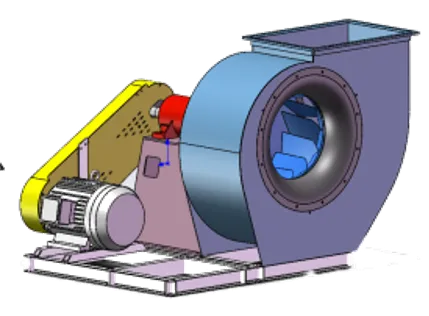

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

Low Pressure Fans:

Low-pressure fan series are 4-72 series, 4-73 series, and 4-79 series. Generally used for indoor ventilation in general factories and large buildings, it can be used as input gas, it can also be used as output gas, it can also be used as output gas, it can also be used for forced ventilation of boilers, forging furnaces, etc.

It is characterized by smooth operation, tight structure, low noise, flexible use, small footprint, high efficiency, and good performance in conveying air and other unnatural, harmless to the human body and non-corrosive gases.

Low-pressure fans are mostly used in garage air supply and exhaust systems, civil air defense ventilation systems, textile exhausts, grain warehouse dry exhausts, and other total air supply and exhaust systems.

Medium Pressure Fans:

The basic models of medium-pressure fans are 5-51 series, 6-51 series, 5-47/5-48 series, and 6-41 series. These models’ air volume and pressure are lower than those of the low-pressure series. Good aerodynamic performance, high efficiency, low noise, smooth operation.

G, Y6-51 type boiler feed fan is mainly used for 2~670t/h steam in thermal power plants.

The air supply system of the boiler also meets the requirements of the performance parameters of the high-pressure head of the fluidized bed furnace. change

Series fans can also be used for dust removal, mine ventilation, and general ventilation systems.

The blower transports air, and the induced draft fan transports gas containing impurity particles.

When the impurity concentration is less than 200mg/m³, it can be used for over 4 years. If the dust content is too large, the blade should be treated with wear-resistant treatment to extend its service life. G series fans are generally normal temperature; The maximum temperature of Y series induced draft fan shall not exceed 250℃. If more than 250℃. The impeller material should be changed.

High Pressure Fans:

Valve Factory:

Our unwavering commitment to excellence encompasses a comprehensive 24/7 on-site service, ensuring you immediate access to top-tier maintenance support whenever needed. We understand that operational efficiency is critical, so our team is always ready to assist you, regardless of the time or day.

Proactive Maintenance Approach

Detailed User Profiles: We take the time to develop thorough user profiles tailored to your specific systems and needs. This personalized approach allows us to understand the intricacies of your operations and tailor our support accordingly.

Regular Site Visits: Our team conducts routine site visits to monitor system performance and identify potential issues before they escalate. This proactive strategy ensures that we address any operational challenges swiftly, minimizing downtime and disruption to your workflow.

Comprehensive Support

Expert Technicians: Our highly trained technicians bring expertise and experience to every interaction, providing you with knowledgeable insights and effective solutions. You can trust that your systems are in capable hands.

Tailored Solutions: We prioritize your unique requirements, offering customized solutions that enhance your system’s performance and reliability. Our goal is to ensure that your operations run seamlessly.

With our dedicated support, you can enjoy peace of mind knowing that your success is our top priority. We are committed to fostering a collaborative partnership, where your needs drive our services. Our responsive support team is always just a call away, ready to assist with any challenges you may encounter.

Experience the difference that our comprehensive, proactive maintenance and exceptional support can make in your operations. Together, we will ensure your systems operate at their best, empowering your success every step of the way!