T35 Axial Flow Fans

T35 Axial Flow Fans are outstanding solutions for effective airflow management across diverse applications. Designed for high performance, these fans excel in providing efficient ventilation and cooling in both industrial and commercial environments. Their sturdy construction and advanced engineering guarantee optimal airflow while reducing energy consumption, making them an excellent choice for discerning users.

In addition to their impressive efficiency, T35 Axial Flow Fans are known for their durability and quiet operation. This combination makes them suitable for a wide range of settings, including industrial facilities, commercial spaces, and agricultural applications. By following proper installation and maintenance protocols, users can fully leverage the capabilities of these fans, fostering a comfortable atmosphere that enhances productivity.

Whether your goal is to improve ventilation in large areas or to find a dependable cooling solution, T35 Axial Flow Fans provide exceptional performance tailored to your specific requirements. Discover the impact of superior airflow management and boost your operational efficiency with T35 Axial Flow Fans.

T35 Axial Flow Fans Parameter:

Get in Touch for Specific Dimensions

Key Characteristics of T35 Axial Flow Fans:

Exceptional Energy Efficiency

T35 Axial Flow Fans are designed to deliver outstanding airflow rates while significantly reducing energy consumption compared to traditional fans. This high efficiency not only boosts operational performance but also results in notable cost savings on energy bills, making these fans a financially smart choice for any business.

Robust and Long-Lasting Construction

Built with high-quality materials, T35 Axial Flow Fans are engineered to endure the demands of challenging environments. Their sturdy design offers excellent resistance to wear and tear, ensuring reliable and long-term performance. Whether in industrial or commercial settings, these fans maintain their effectiveness over time, minimizing the need for frequent replacements.

Space-Saving Design

The streamlined and compact design of T35 Axial Flow Fans allows for easy installation in confined spaces where larger fans may be impractical. This versatility makes them suitable for various applications, from warehouses to greenhouses, where effective airflow management is essential but space is at a premium.

Quiet Performance

Minimizing noise is crucial in many environments. T35 Axial Flow Fans are engineered to operate quietly, contributing to a comfortable and distraction-free atmosphere. This is particularly advantageous in office settings, retail spaces, and other environments where a peaceful ambiance is vital for both productivity and customer satisfaction.

Adjustable Speed Settings

Flexibility in airflow management is key, and many T35 models feature variable speed options. This allows users to tailor the airflow to their specific requirements, whether they need a gentle breeze or robust ventilation. By adjusting the fan speed, users can optimize energy efficiency while ensuring their environment remains comfortable and well-ventilated.

Usage Method of T35 Axial Flow Fans:

Using T35 Axial Flow Fans is straightforward and efficient. Here’s a comprehensive guide to help you achieve maximum performance:

Installation Steps

- Select an Ideal Location:

- Choose a location that offers unobstructed airflow. Ensure there are no obstacles nearby that could hinder the fan’s performance. Consider factors such as the direction of prevailing winds and the layout of the space to maximize airflow efficiency.

- Secure the Fan:

- Mount the fan securely using the provided brackets. Ensure that the fan is level to minimize vibrations and enhance stability. This will not only improve performance but also extend the lifespan of the fan. If possible, use vibration-dampening materials to further reduce noise.

- Connect the Wiring:

- Carefully follow the manufacturer’s guidelines and local safety regulations for electrical connections. Double-check connections to ensure they are secure and insulated. If you are unsure, consider consulting a professional electrician to guarantee safety and compliance.

Operation Guidelines

- Adjust the Fan Speed:

- Utilize the variable speed settings to customize the airflow according to your specific needs. For example, increase the speed for high-demand situations, such as during peak usage times, and decrease it when lower airflow is sufficient. This flexibility helps strike the right balance between airflow and energy efficiency, contributing to cost savings.

- Monitor Performance:

- Regularly check the fan’s performance to ensure it operates at optimal levels. Look for signs of wear, unusual noises, or changes in airflow. Make necessary adjustments to the speed settings and inspect the fan’s components as needed to maintain comfort and efficiency.

- Routine Maintenance:

- Implement a routine maintenance schedule to clean the fan and check for any buildup of dust or debris that may obstruct airflow. Regularly inspect the wiring and mechanical components to ensure they are in good condition. This proactive approach can prevent potential issues and prolong the fan’s lifespan.

- Evaluate Environmental Conditions:

- Consider the specific conditions of the environment where the fan is installed. Factors such as temperature, humidity, and air quality can affect performance. Adjust the fan settings accordingly to optimize comfort and efficiency in response to changing conditions.

By adhering to these steps, you can ensure that your T35 Axial Flow Fans operate efficiently, providing consistent airflow and enhancing the overall comfort of your environment. Experience the benefits of effective airflow management with minimal effort.

T35 Axial Flow Fans Application:

T35 Axial Flow Fans are highly versatile and efficient, making them ideal for a variety of applications across different industries. Their robust construction and superior performance facilitate effective airflow management in numerous environments. Here are some notable applications:

- Data Centers

- Temperature Control: Critical for maintaining optimal operating temperatures in data centers, T35 fans help protect sensitive electronic equipment from overheating.

- Energy Efficiency: By optimizing airflow, these fans contribute to cooling efficiency, thereby reducing energy costs and enhancing overall operational performance.

- Agricultural Operations

- Greenhouse Ventilation: Essential for regulating temperature and airflow in greenhouses, T35 fans support healthy plant growth and create optimal cultivation conditions.

- Animal Housing: Improve air quality in barns and livestock facilities, promoting the health and productivity of animals while reducing odors.

- Mining and Tunnel Applications

- Worker Safety: Ensure adequate ventilation in mines and tunnels, significantly enhancing air quality for improved worker safety.

- Heat Management: Help control heat levels in confined spaces, making work environments safer and more comfortable for personnel.

- Industrial Settings

- Equipment Cooling: Perfect for cooling machinery in manufacturing plants, T35 fans help prevent overheating and maintain efficient operating conditions.

- Exhaust Systems: Effectively remove heat, smoke, and fumes from production areas, creating a safer working environment for employees.

- Commercial Spaces

- HVAC Integration: Enhance air circulation within heating, ventilation, and air conditioning systems, thereby improving indoor air quality and overall comfort.

- Retail Environments: Provide essential ventilation in large retail spaces, ensuring a pleasant shopping atmosphere for customers while preserving product quality.

- Food Processing and Storage

- Cooling and Drying Applications: Used in food processing facilities for cooling equipment and drying products, ensuring compliance with safety and quality standards.

- Storage Ventilation: Maintain proper airflow in food storage areas to prevent spoilage and extend the shelf life of products.

Overall, T35 Axial Flow Fans offer robust solutions tailored to meet the specific needs of various industries, enhancing airflow management and operational efficiency across diverse applications.

Fans Type:

Centrifugal fans can be categorized based on pressure levels into three main types: low pressure (P ≤ 1000 Pa), medium pressure (P = 1000–5000 Pa), and high pressure (P = 5000–30000 Pa).

Low-Pressure Fans

Typically represented by series such as 4-72, 4-73, 4-68, and 4-79, low-pressure fans feature blades that are primarily backward inclined, usually at an angle of about 45 degrees. These fans are known for their large airflow capacity, low noise levels, and stable operation, making them ideal for general ventilation applications.

Medium Pressure Fans

Medium-pressure fans, including series like 5-51, 6-30, 6-41, and 6-51, have a larger outlet angle than low-pressure fans, typically around 50 degrees. They also provide significant airflow while maintaining low noise levels and are less prone to overload. This makes them suitable for a variety of ventilation needs.

High-Pressure Fans

High-pressure fans, represented by 9-19, 9-26, 9-12, and 8-09, generally feature forward-tilted blades with angles less than 90 degrees. These fans are designed to supply forced air effectively and are utilized when higher pressure is required.

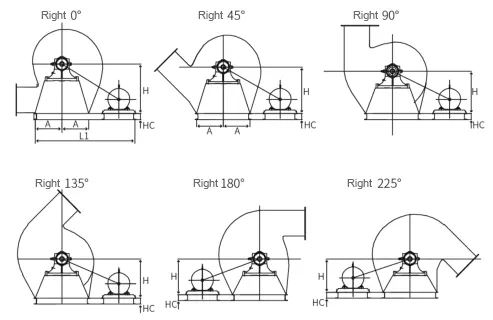

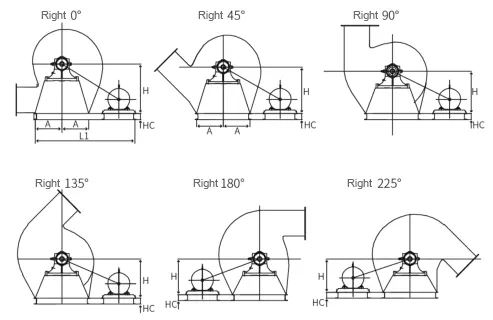

Direction of Rotation

When viewed from the motor side, fans can rotate in two directions: counterclockwise (left) or clockwise (right).

Angle Options

The fan blade angles are categorized as follows: 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

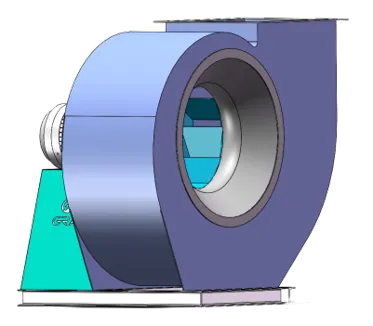

Type A Direct Transmission:

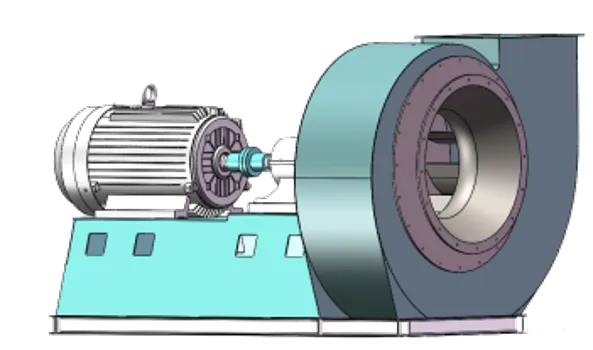

Type D Direct Transmission:

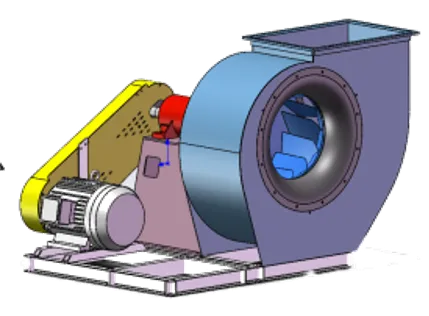

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

Low Pressure Fans:

Low-pressure fan series, including the 4-72, 4-73, and 4-79 models, are primarily designed for indoor ventilation in general factories and large buildings. These fans can function as both intake and exhaust systems and are also suitable for forced ventilation in applications such as boilers and forging furnaces.

- Smooth Operation: Ensures reliable performance with minimal vibration.

- Compact Design: Occupies a small footprint, making it easy to integrate into various spaces.

- Low Noise Levels: Operates quietly, contributing to a comfortable environment.

- High Efficiency: Delivers effective air movement while consuming less energy.

- Versatile Usage: Capable of handling air and other non-corrosive, harmless gases without affecting human health.

Low-pressure fans are widely used in:

- Garage Ventilation: For air supply and exhaust in parking facilities.

- Civil Defense Systems: Ensuring adequate air circulation in emergencies.

- Textile Industry: Used for exhaust systems to maintain air quality.

- Grain Storage: Assisting in the drying process within grain warehouses.

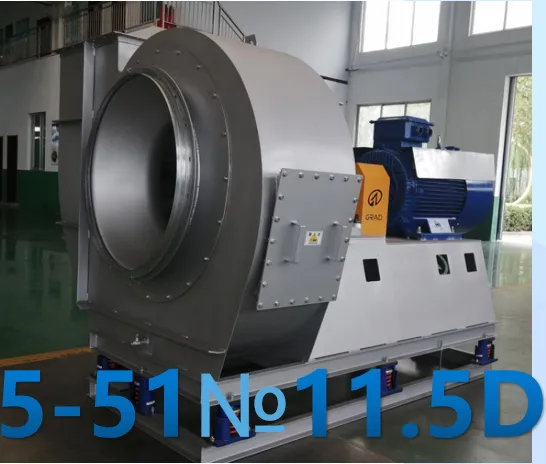

Medium Pressure Fans:

The primary models of medium-pressure fans include the 5-51, 6-51, 5-47/5-48, and 6-41 series. These fans deliver lower air volumes and pressures compared to low-pressure fans, yet they are known for their excellent aerodynamic performance, high efficiency, low noise levels, and smooth operation.

Applications

- Boiler Feed Fans: The G and Y6-51 models are specifically designed for use in thermal power plants, catering to steam generation capacities ranging from 2 to 670 tons per hour. These fans ensure that the air supply system of the boiler meets the performance parameters required for high-pressure head applications, such as fluidized bed furnaces.

- Dust Removal and Mine Ventilation: These fans are also effective in dust extraction and general ventilation systems.

Functionality

- Air Transport: These fans are primarily used for transporting air, while induced draft fans are designed to handle gases containing impurity particles.

- Dust Handling: They can operate effectively when the concentration of impurities is below 200 mg/m³ for over four years. However, if the dust levels are high, the blades should be treated with wear-resistant coatings to enhance their durability.

Temperature Specifications

- G Series Fans: Typically designed for normal temperature operations.

- Y Series Induced Draft Fans: Can withstand temperatures up to 250°C. If operating conditions exceed this temperature, it is advisable to switch to materials better suited for higher heat to ensure optimal performance and longevity.

In summary, medium-pressure fans are versatile and efficient, suitable for various applications, including boiler feed systems and ventilation, while offering adaptability to different operational conditions.

High Pressure Fans:

Fans Factory:

Our unwavering commitment to excellence encompasses a comprehensive 24/7 on-site service, ensuring that you have immediate access to top-tier maintenance support whenever you need it. We understand that operational efficiency is critical, which is why our team is always ready to assist you, regardless of the time or day.

Proactive Maintenance Approach

Detailed User Profiles: We take the time to develop thorough user profiles tailored to your specific systems and needs. This personalized approach allows us to understand the intricacies of your operations and tailor our support accordingly.

Regular Site Visits: Our team conducts routine site visits to monitor system performance and identify potential issues before they escalate. This proactive strategy ensures that we address any operational challenges swiftly, minimizing downtime and disruption to your workflow.

Comprehensive Support

Expert Technicians: Our highly trained technicians bring expertise and experience to every interaction, providing you with knowledgeable insights and effective solutions. You can trust that your systems are in capable hands.

Tailored Solutions: We prioritize your unique requirements, offering customized solutions that enhance your system’s performance and reliability. Our goal is to ensure that your operations run seamlessly.

With our dedicated support, you can enjoy peace of mind knowing that your success is our top priority. We are committed to fostering a collaborative partnership, where your needs drive our services. Our responsive support team is always just a call away, ready to assist with any challenges you may encounter.

Experience the difference that our comprehensive, proactive maintenance and exceptional support can make in your operations. Together, we will ensure your systems operate at their best, empowering your success every step of the way!