Zinc-Coated Integrated Valve

The Zinc-Coated Integrated Valve presents an advanced option for effective fluid control in a variety of applications. Crafted for durability and efficiency, this valve features a protective zinc coating that significantly enhances its resistance to corrosion, ensuring dependable performance even in challenging environments. Its integrated design simplifies the installation process and facilitates easy maintenance, making it a preferred choice for engineers and contractors alike.

Esteemed for its reliability and efficiency, the Zinc-Coated Integrated Valve is an essential component of any fluid management system. Its corrosion-resistant properties, coupled with a user-friendly design, increase its utility across diverse settings. By following proper usage and maintenance practices, users can maximize the valve’s performance and prolong its lifespan. Opt for the Zinc-Coated Integrated Valve to enhance your fluid management systems and ensure lasting reliability.

Zinc-Coated Integrated Valve Parameter:

Get in Touch for Specific Dimensions

Key Characteristics of Zinc-Coated Integrated Valve:

1. High Flow Efficiency

The Zinc-Coated Integrated Valve is engineered to optimize fluid flow, minimizing pressure loss while maximizing throughput. This design enhances overall system performance, ensuring smooth and effective operation in industrial and residential settings. This valve guarantees reliable fluid delivery when faced with high-demand conditions or routine use.

2. User-Friendly Design

The valve’s straightforward mechanism makes operation simple for all experience levels. Anyone can easily open and close the valve without specialized training or tools, promoting accessibility and safety. This intuitive design empowers professionals and DIY enthusiasts to confidently engage with the valve.

3. Corrosion Protection

This valve has a robust zinc coating and protects against rust and environmental wear. This corrosion resistance significantly extends the valve’s lifespan and reduces maintenance costs, making it an ideal option for residential and industrial uses. Users can rely on the valve to perform consistently, even under harsh conditions, ensuring lasting peace of mind.

4. Integrated Functionality

The innovative integrated design consolidates multiple functions into a single unit, streamlining installation and reducing potential points of failure. This valve simplifies setup by minimizing the number of components, allowing for quicker installations and less downtime. Engineers and contractors will appreciate the efficiency and ease this design brings to their projects.

5. Versatile Usage

The adaptability of the Zinc-Coated Integrated Valve allows it to be utilized in various applications, from plumbing and HVAC systems to industrial processes. Its capability to handle a wide range of fluid types and pressures makes it a preferred choice for engineers aiming to enhance fluid management in diverse environments, including residential buildings and large industrial facilities.

Usage Method of Zinc-Coated Integrated Valve:

The Zinc-Coated Integrated Valve is designed for optimal fluid control, and proper usage is key to achieving peak performance. This guide outlines the essential steps for installation, operation, and system integration.

Installation

1. Prepare the Installation Area

- Ensure the installation site is clean and free of debris to minimize contamination risks and ensure a proper seal.

- Check for any existing components or systems that might obstruct the valve’s installation.

2. Connect the Valve

- Use compatible fittings that match the valve’s specifications and the existing piping system to prevent leaks.

- Align the valve correctly with the piping to maintain a straight flow path.

3. Secure the Connections

- Tighten all connections according to the recommended torque specifications. Avoid over-tightening, which can damage the valve, and under-tightening, which may lead to leaks.

- After installation, inspect all joints and connections for misalignment or potential leaks.

Operation

1. Adjusting the Valve

- Rotate the handle or lever as per the model’s specifications to open or close the valve. Some models may employ a quarter-turn mechanism, while others may require several turns.

- Ensure the valve operates smoothly without any sticking or excessive force.

2. Monitoring Fluid Flow

- Regularly check for any inconsistencies in fluid flow, such as pressure fluctuations or unexpected volume changes.

- If issues arise, make necessary adjustments to the valve to restore proper flow. Consider installing flow meters for real-time monitoring of the fluid dynamics.

Zinc-Coated Integrated Valve Application:

The Zinc-Coated Integrated Valve is renowned for its durability and corrosion resistance, making it suitable for various applications. Here are various settings where this valve demonstrates its versatility and effectiveness:

1. Irrigation Systems

- Agricultural Irrigation: Commonly used in farming, this valve ensures efficient water distribution for crop irrigation, providing essential hydration for optimal plant growth.

- Landscape Irrigation: Landscaping effectively manages water flow for gardens and lawns, promoting sustainable water practices.

2. HVAC Systems

- Airflow Management: The valve is vital in HVAC systems, controlling airflow to various building areas to maintain comfort and enhance energy efficiency.

- Chilled Water Applications: It regulates coolant flow in chilled water systems, contributing to adequate heating and cooling cycles.

3. Industrial Applications

- Manufacturing Processes: The key to manufacturing is that this valve enables precise control of liquid flow in cooling systems, chemical mixing, and lubrication tasks.

- Chemical Processing: Designed to handle aggressive chemicals, it is ideal for chemical plants, where it safely manages the flow of different substances.

4. Plumbing Systems

- Residential Plumbing: Widely used in household plumbing, the valve controls water flow to faucets, toilets, and showers, ensuring longevity even in high-moisture environments.

- Commercial Plumbing: In commercial buildings, these valves effectively manage water supply for restrooms, kitchens, and other facilities, ensuring efficient operation and minimal downtime.

5. Fire Protection Systems

- Sprinkler Systems: This valve is essential in fire sprinkler systems, opening and closing to regulate water distribution during emergencies, ensuring a rapid response.

- Standpipe Systems: In commercial buildings, it maintains pressure in fire suppression systems, ensuring readiness for any emergency situation.

6. Water Treatment Plants

- Flow Regulation: In water treatment facilities, the valve controls the flow of treated and untreated water, playing a crucial role in purification and distribution.

- Chemical Dosing: It manages the addition of chemicals used in water treatment processes, ensuring accurate dosing for effective purification.

7. Marine Applications

- Boat Systems: In marine settings, the valve regulates water intake and discharge, ensuring safe and efficient operation.

- Cooling Systems: It controls coolant flow in marine engines, preventing overheating and ensuring optimal performance in challenging conditions.

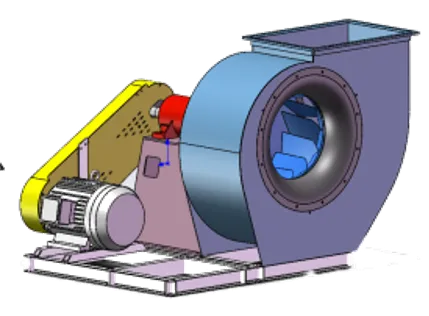

Fans Type:

General centrifugal fans can be divided into low pressure (P≤1000Pa), medium pressure (P=1000-5000Pa), and high pressure (P=5000-30000Pa) according to the pressure. Low-pressure fans are generally 4-72, 4-73, 4-68, 4-79, and other backward blade series. Medium pressure fans are generally 5-51, 6-30, 6-41, 6-51, and other series; High pressure is generally 9-19, 9-26, 9-12, and 8-09 series. The low-pressure fan blades are mostly backward inclined blades, generally about 45 degrees. The outlet Angle of medium pressure fan is larger than that of low pressure fan. It is generally about 50 degrees, and the blades of the high-pressure fan are generally tilted forward less than 90 degrees. The advantages of medium and low-pressure fans are large flow, low noise value, not easy to overload, relatively stable operation, and use in general ventilation. High-pressure fans are used to supply forced air.

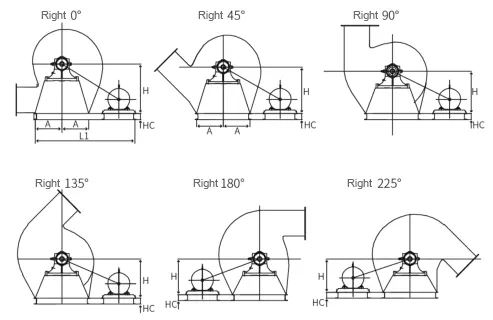

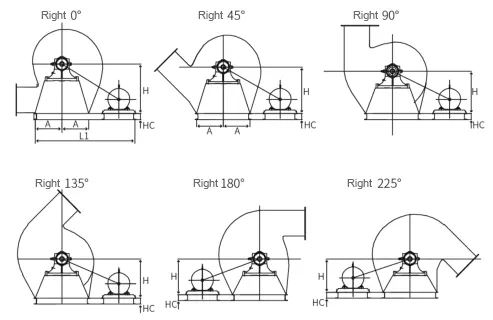

From the direction of the drive side (motor), the counterclockwise rotation is left, and the clockwise rotation is right.

The Angle is generally divided into 0 degrees, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, and 270 degrees.

Type A Direct Transmission:

Type D Direct Transmission:

Type C Belt Transmission:

Type E Belt Transmission:

Type E Direct Transmission:

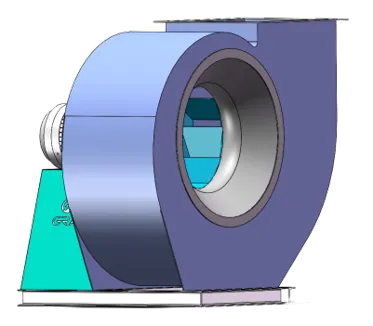

Low Pressure Fans:

Low-pressure fan series are 4-72 series, 4-73 series, and 4-79 series. Generally used for indoor ventilation in general factories and large buildings, it can be used as input gas, it can also be used as output gas, it can also be used as output gas, it can also be used for forced ventilation of boilers, forging furnaces, etc.

It is characterized by smooth operation, tight structure, low noise, flexible use, small footprint, high efficiency, and good performance in conveying air and other unnatural, harmless to the human body and non-corrosive gases.

Low-pressure fans are mostly used in garage air supply and exhaust systems, civil air defense ventilation systems, textile exhausts, grain warehouse dry exhausts, and other total air supply and exhaust systems.

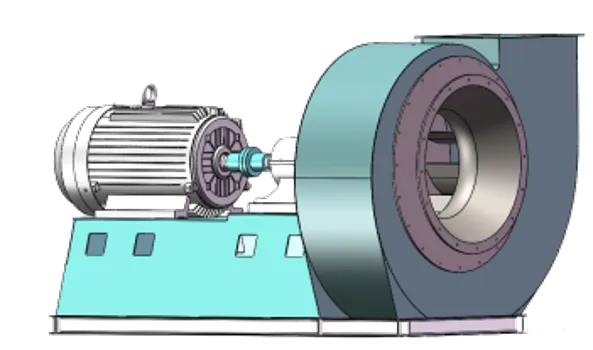

Medium Pressure Fans:

The basic models of medium-pressure fans are 5-51 series, 6-51 series, 5-47/5-48 series, and 6-41 series. These models’ air volume and pressure are lower than those of the low-pressure series. Good aerodynamic performance, high efficiency, low noise, smooth operation.

G, Y6-51 type boiler feed fan is mainly used for 2~670t/h steam in thermal power plants.

The air supply system of the boiler also meets the requirements of the performance parameters of the high-pressure head of the fluidized bed furnace. change

Series fans can also be used for dust removal, mine ventilation, and general ventilation systems.

The blower transports air, and the induced draft fan transports gas containing impurity particles.

When the impurity concentration is less than 200mg/m³, it can be used for over 4 years. If the dust content is too large, the blade should be treated with wear-resistant treatment to extend its service life. G series fans are generally normal temperature; The maximum temperature of Y series induced draft fan shall not exceed 250℃. If more than 250℃. The impeller material should be changed.

High Pressure Fans:

Valve Factory:

Our unwavering commitment to excellence encompasses a comprehensive 24/7 on-site service, ensuring you immediate access to top-tier maintenance support whenever needed. We understand that operational efficiency is critical, so our team is always ready to assist you, regardless of the time or day.

Proactive Maintenance Approach

Detailed User Profiles: We take the time to develop thorough user profiles tailored to your specific systems and needs. This personalized approach allows us to understand the intricacies of your operations and tailor our support accordingly.

Regular Site Visits: Our team conducts routine site visits to monitor system performance and identify potential issues before they escalate. This proactive strategy ensures that we address any operational challenges swiftly, minimizing downtime and disruption to your workflow.

Comprehensive Support

Expert Technicians: Our highly trained technicians bring expertise and experience to every interaction, providing you with knowledgeable insights and effective solutions. You can trust that your systems are in capable hands.

Tailored Solutions: We prioritize your unique requirements, offering customized solutions that enhance your system’s performance and reliability. Our goal is to ensure that your operations run seamlessly.

With our dedicated support, you can enjoy peace of mind knowing that your success is our top priority. We are committed to fostering a collaborative partnership, where your needs drive our services. Our responsive support team is always just a call away, ready to assist with any challenges you may encounter.

Experience the difference that our comprehensive, proactive maintenance and exceptional support can make in your operations. Together, we will ensure your systems operate at their best, empowering your success every step of the way!